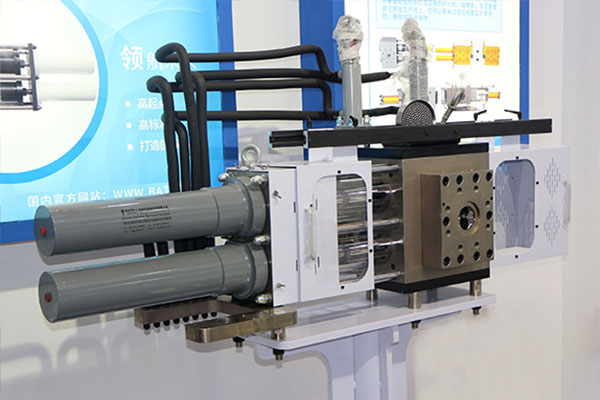

Backflush extrusion screen changer

Backflush extrusion screen changer is a kind of self cleaning screen changer with the design of four channels and four filters. The four filters of backflush screen changer are working simultaneously without stopping material flowing or mass production.

Hydraulic Backflush Screen Changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DPF-4R-120

|

260~760

|

180

|

1160

|

220

|

Ф100

|

78×4

|

6

|

230/400

|

1.0/1.3

|

|

ZB-DPF-4R-145

|

580~1400

|

225

|

1420

|

270

|

Ф125

|

123×4

|

6

|

230/400

|

2.0/2.4

|

|

ZB-DPF-4R-170

|

750~2000

|

260

|

1595

|

310

|

Ф150

|

177×4

|

6

|

230/400

|

3.0/3.5

|

|

ZB-DPF-4R-195

|

1350~3000

|

315

|

1890

|

380

|

Ф175

|

240×4

|

6

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-220

|

1650~3800

|

350

|

2100

|

410

|

Ф200

|

314×4

|

10

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-250

|

2100~5200

|

405

|

2395

|

460

|

Ф230

|

415×4

|

12

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-280

|

4500~8500

|

450

|

2760

|

500

|

Ф250

|

490×4

|

12

|

230/400

|

4.2/5.0

|

Backflush self cleaning extrusion screen changer Characteristics:

The exhaust air system is able to fully discharge the air inside the material or perforated plate which are to be replaced. It can avoid air forming in the product during screen changing, thus improve the product quality.

The backflush function can achieve non-stop backflushing filter. The filter can be recycled for more than 200 times.

Four channel design greatly increase filtering area, and meet the higher quality or quantity production demand.

Bigger filtering area are applicable for different material or extrusion products.

It has better sealing characteristics with rigid sealing. The service life is longer.

It is applicable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.

It is especially applicable for recycled plastics or large proportion of recycled plastic.

With its automatic cleaning filter function, the frequent screen changing can be avoided.

It can increase output and save energy consumption.

We can customize various sizes or standards based on the client's requirement.

It is configured with safety production cover design.

It has reasonable structure design, easier operation and better working effect.

Backflush extrusion screen changer Application:

Self cleaning screen changer is used for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling pelletizing, etc.

Relative Articles:

◆Single piston screen changer

◆Double piston screen changer with four screen cavities

◆Double plate fast screen changer with 2 cavities

◆Single slide plate screen changer

◆Double plate screen changer with two screen cavities

◆Manual screen changers

◆Double piston screen changers with two cavities

◆Four screen cavities screen changer

◆Automatic continuous belt screen changer