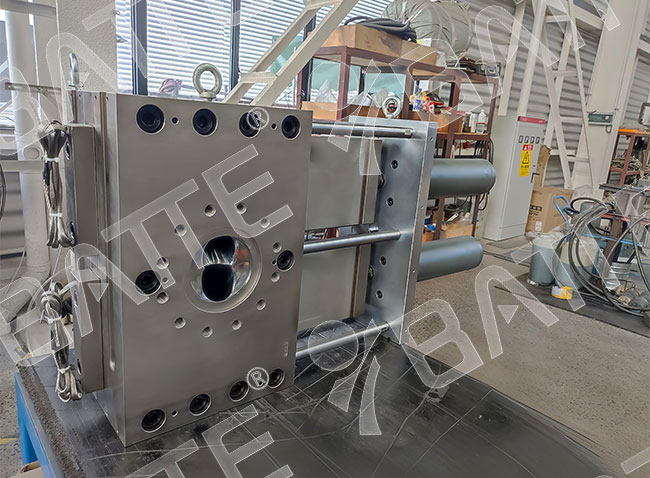

hydraulic double plate continuous screen changer

We provide single-plate, double-plate, single-column, double-column screen changer . Changing the screen hydraulically for easy production and maintenance.

The filtering channels of double-plate four-position unit may work alternately, contributing to quick screen change-over , easy production and simple maintenance.

Come with built-in sealing device to ensure sound tightness and allow for mass production of any polymers, capable of being coupled with extruders of various specifications.

The screen change-over duration for the double-position quick screen changer ≤1 second. The filter area is optional from Φ30 to Φ250mm.

Come with grinding-resistant, pressure-resistant and high precision filter to ensure maximized filtering area and optimized filtering results.

Its performance will not be compromised when the pressure is kept between 25—30Mpa and temperature around 300°C

Nearly all the polymers are fit for screen changer, such as PC, PMMA, PET, PS, PU, PP, PE, EVA, ABS, etc.

Application:1.Non-woven.2.Granulation.3.Pipe.4.Plate.5.Sheet.6.Cast film.

Double plate screen changer supplier performance characteristic:

1. The double plate screen changer works simultaneously: when one net works, the other one replaced.

2. Exhaust system device can fully defuse the gas mixed in the materials and improve the product quality.

3. Double channels expand the filtration area to produce more high-quality production which meet the customers’ need.

4. Apply to extrusion production in a wide range of materials and product.

5. Good sealing system ensures perfect sealing effect.

6. The function of filling material exhaust and pollution discharge guarantee the process of replacing screen continuously.

7. We design and manufacture production of various sizes according to the customers’ requirement.

8. A well-designed structure makes operation more convenient .

Hydraulic double plate continuous screen changer commissioning

At the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

double plate screen changer

Double slide plate double hydraulic screen changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-2R-80

|

30~180

|

100

|

800

|

170

|

Ф60

|

28×2

|

6

|

230/400

|

0.5/0.7

|

|

ZB-DP-2R-100

|

80~280

|

110

|

830

|

200

|

Ф80

|

50×2

|

6

|

230/400

|

0.8/1.1

|

|

ZB-DP-2R-120

|

130~380

|

125

|

850

|

220

|

Ф100

|

78×2

|

6

|

230/400

|

0.9/1.2

|

|

ZB-DP-2R-145

|

300~700

|

165

|

1020

|

270

|

Ф125

|

123×2

|

6

|

230/400

|

1.4/1.8

|

|

ZB-DP-2R-170

|

400~1100

|

195

|

1120

|

310

|

Ф150

|

177×2

|

6

|

230/400

|

1.6/2.2

|

|

ZB-DP-2R-195

|

650~1500

|

220

|

1270

|

380

|

Ф175

|

240×2

|

6

|

230/400

|

2.5/3.5

|

|

ZB-DP-2R-220

|

850~1900

|

245

|

1350

|

410

|

Ф200

|

314×2

|

10

|

230/400

|

2.3/2.8

|

|

ZB-DP-2R-250

|

1100~2600

|

280

|

1500

|

460

|

Ф230

|

415×2

|

12

|

230/400

|

2.5/3.2

|

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

(mm)L*W

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-2E-120

|

200~800

|

150

|

850

|

220

|

100×145

|

124×2

|

6

|

230/400

|

0.8/1.2

|

|

ZB-DP-2E-145

|

400~1100

|

165

|

1020

|

270

|

125×170

|

179×2

|

6

|

230/400

|

1.4/2.0

|

|

ZB-DP-2E-170

|

680~1500

|

220

|

1300

|

310

|

150×230

|

296×2

|

6

|

230/400

|

1.6/2.2

|

|

ZB-DP-2E-195

|

1000~2600

|

240

|

1420

|

380

|

175×270

|

406×2

|

6

|

230/400

|

2.5/3.5

|

|

ZB-DP-2E-220

|

2300~4400

|

280

|

1665

|

410

|

200×300

|

514×2

|

10

|

230/400

|

2.5/3.2

|

|

ZB-DP-2E-250

|

2900~6000

|

310

|

1720

|

460

|

230×310

|

600×2

|

12

|

230/400

|

2.8/3.5

|

|

ZB-DP-2E-270

|

2900~6000

|

350

|

1900

|

500

|

250×345

|

737×2

|

12

|

230/400

|

3.2/4.0

|