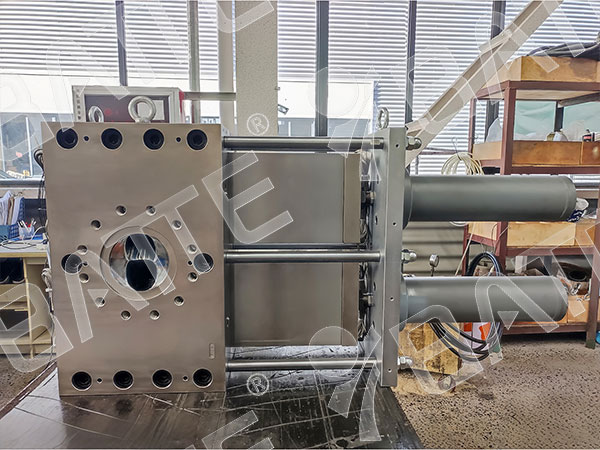

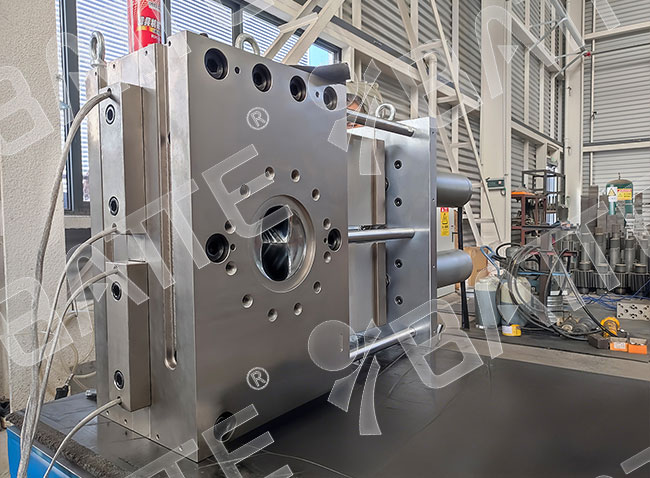

Double-Plate Hydraulic Continuous Screen Changer

The double-plate hydraulic screen changer is a high-efficiency filtration device used in production processes such as plastic extrusion. It primarily enables non-stop screen replacement to ensure continuous production.

Structure and Working Principle

Structure: The double-plate hydraulic screen changer features a split-type dual-plate, dual-flow-channel design, consisting of two independent filter plates. Each filter plate is equipped with a screen and corresponds to a hydraulic drive unit and sealing structure.

Working Principle: Both filter positions can operate simultaneously. When the pressure on one filter reaches a preset value, the hydraulic system automatically initiates the switching program. This drives the corresponding filter plate to slide, moving the clogged filter position out of the melt flow channel while simultaneously bringing the standby filter position into the flow channel. This achieves the alternation between the old and new filters, with the entire process typically taking only a few seconds.

Features

High Production Efficiency: Dual-station alternating operation enables mesh changes without shutdown, boosting equipment utilization by over 20% compared to traditional changers.

Stable Pressure: Rational material feeding and venting structures minimize pressure and flow fluctuations during changes, ensuring consistent product quality.

User-Friendly Operation: Screen changes are executed via hydraulic handles or intelligent control systems, reducing manual intervention and labor intensity.

Reliable Sealing: Utilizes flexible pressure-activated seals or cooling water-cured sealing technology, withstanding high pressure (25-30MPa) and temperatures (≤300℃) to effectively prevent melt leakage.

Large Filtration Area: The dual-screen structure doubles the filtration area, effectively removing impurity particles to ensure melt quality.

Versatile Heating Options: Choose between electric heating or thermal fluid heating based on specific requirements to meet diverse process temperature demands.

Application Scenarios

Plastic Processing: Widely used in plastic pelletizing, film blowing, pipe, sheet, and plate extrusion, as well as chemical fiber spinning.

Recycling Sector: Plays a vital role in high-filtration-demand processes like recycled plastic regeneration and underwater pelletizing.

High-End Manufacturing: Enhances premium product yield in production requiring high quality standards, such as PE pipes and PP fibers, when using double-plate hydraulic screen changers.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071