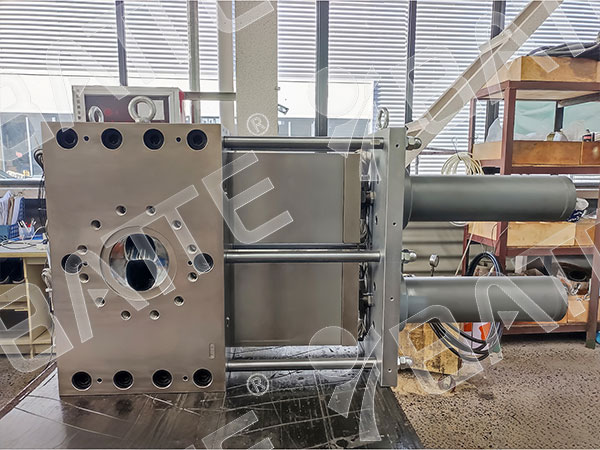

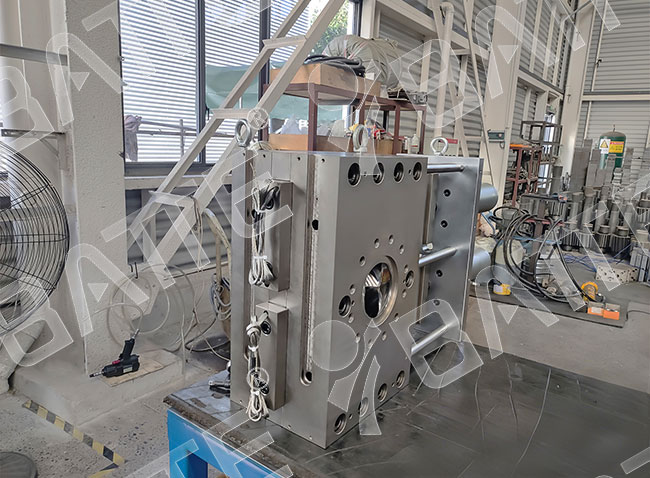

Double-Plate Screen Changer for ∅350mm Pelletizing Extruders

For large-scale pelletizing extruders with a diameter of ∅350mm (commonly used for modifying, filling, and recycling pellets of materials such as PE/PP/ABS/PS, typically with an output of 10~30t/h), the double-plate screen changer serves as the mainstream continuous screen changing solution for this machine type.

The dual-plate screen changer (dual-station plate type) is a continuous screen-changing device specifically designed for large-diameter, high-output extruders. Compared to single-plate and column-type screen changers, its core advantages for Φ350mm models include:

Continuous Production Without Shutdowns: Dual plates operate alternately—one side filters melt while the other changes screens—ensuring zero material interruptions or pressure fluctuations. This meets the high-capacity demands of Φ350 extruders, eliminating material waste and output losses caused by shutdowns for screen changes.

Large filtration area for high output: The dual-plate structure provides expanded filter area, matching the large flow channels and high melt flow rates of Φ350 extruders. This extends filter clogging intervals and reduces changeover frequency.

Reliable Sealing, High-Pressure/Temperature Resistance: Designed for pelletizing melts (200–300°C, 10–30 MPa), the dual-plate hydraulic drive + hard-seal structure prevents melt leakage. Suitable for highly abrasive, high-viscosity conditions in modified and filled pelletizing applications.

Smooth flow path with no dead zones: Plate-type flow channels coaxially aligned with Φ350 extruder barrel channels ensure uninterrupted melt flow without degradation, guaranteeing pellet quality—ideal for transparent and heat-sensitive plastics.

Easy maintenance, low cost: Screen replacement requires only hydraulic plate exchange for simple operation. Standard square/rectangular screens significantly reduce procurement costs compared to cylindrical ring screens, making them ideal for large-scale pelletizing production.

Optimization for Φ350 Granulator Operating Conditions

High-Fill Modified Granulation (CaCO₃, talc fillers ≥30%): Select wear-resistant alloy flow channels (surface hardness ≥HRC58), Thicken filter plates (≥40mm thickness) to prevent abrasive wear on channels; Use stainless steel high-density mesh screens to extend clogging intervals.

Recycled Material Pelletizing (Waste Plastics, Sprue Scrap): Increase filtration area (single plate ≥0.15m²), reduce mesh count (20–40 mesh), and incorporate impurity collection chambers to minimize screen changes. Enhance hydraulic system thrust to overcome resistance caused by high impurity levels during plate replacement.

Thermosensitive plastic pelletizing (PVC, EVA): Polished flow channels (roughness Ra ≤ 0.8μm) with dead-zone-free design; enhanced heating control accuracy (±3℃) to prevent melt degradation and discoloration.

High-output conditions (≥25 t/h): Utilize large-diameter flow channels (Φ180 mm), synchronized heating of dual plates, and screen change speeds ≤8 seconds to ensure continuous production and prevent uneven die discharge caused by sudden pressure fluctuations.

Φ350mm pelletizing extruder compatible with dual-plate screen changer, preferably hydraulically driven, dual-plate reciprocating type, flow channel Φ150mm, filtration area ≥0.24m², with a pressure rating of 35MPa. Adjust the mesh size and apply wear-resistant treatment to the flow channels based on the pelletizing material (virgin material / recycled material / modified material). This ensures continuous, efficient, and stable pelletizing production, representing the optimal screen changer solution for this machine type.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071