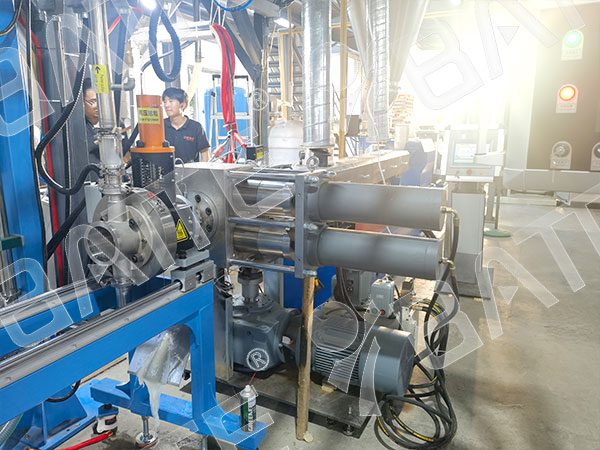

Double column screen changer for plastic granulation production line

The dual-column screen changer serves as the core melt filtration equipment in plastic extrusion pelletizing production lines. Leveraging its dual-column alternating operation design, it enables non-stop screen changes and continuous impurity filtration. This perfectly aligns with the production line's core requirements for continuous operation, high throughput, and stable melt pressure. It stands as the mainstream choice for scenarios such as modified pelletizing and recycled material pelletizing, and masterbatch pelletizing. Compared to single-column and single plate screen changers, it offers significant advantages in screen change efficiency, production continuity, and capacity compatibility.

I. Core Working Principle

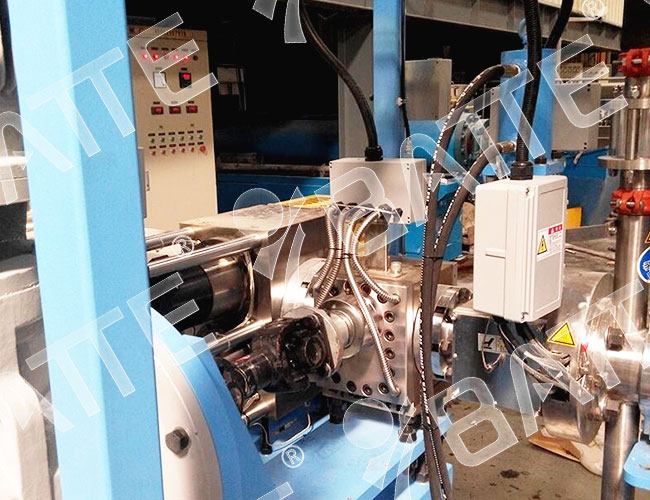

The dual-column screen changer comprises a melt flow channel cavity + two horizontally movable filter columns (each containing a screen assembly). These columns are symmetrically positioned, maintaining a constant operational state where one column filters online while the other performs offline screen changes:

Filtering Phase: Melt enters the changer from the extruder barrel, passing through the filter screen assembly of the online column. Impurities are captured by the screen, while purified melt flows through the channel to the subsequent pelletizing system.

Screen Change Phase: When the online screen becomes clogged and melt pressure reaches the preset value, the hydraulic drive mechanism pushes both columns to move laterally. The clogged filter column switches to the offline position, while the clean spare filter column switches to the online position. The entire screen change process occurs without interrupting the melt flow path or requiring production line shutdown.

Cleaning Phase: The offline column allows for rapid filter removal and impurity cleaning during production. After installing a new filter, it awaits the next changeover, enabling continuous operation.

The entire changeover takes only 3-10 seconds, with minimal melt pressure fluctuation. This prevents production line downtime, material strand breakage, and inconsistent pellet quality issues typically caused by manual changeovers.

II. Core Adaptive Value for Production Lines

Plastic granulation (especially recycled material and modified granulation) often involves feedstock containing plastic carbon, metal shavings, glass fiber fragments, sand, and film scrap impurities. Failure to filter these can cause die wear in pelletizers, particle appearance defects, and damage to downstream processing equipment. The dual-column screen changer precisely addresses these granulation pain points:

Ensures continuous production: Non-stop screen changes eliminate the traditional “shutdown-screen removal-cleaning-restart” process, boosting single-shift output by 15%-30%. This is particularly suited for recycled material granulation with high impurity levels and prone to screen clogging.

Stabilizes melt process parameters: Maintains melt pressure and temperature fluctuations below ±5 bar during screen changes, preventing pressure surges that cause extruder screw speed fluctuations and uneven melt extrusion. Ensures uniform particle size and consistent density.

Compatible with high-capacity pelletizing lines: The dual-column structure features larger flow channels (standard DN40-DN300) and higher melt throughput, supporting both single-screw and twin-screw extruder pelletizing lines (capacity range: 50kg/h to 8000kg/h). This accommodates diverse needs from laboratory pilot testing to industrial-scale production.

Reduces labor and material waste: No shutdowns or restarts required, minimizing material buildup in the die and waste pellets caused by downtime (1%-3% reduction in waste per ton of material); Screen changes require only 1-2 operators, significantly lowering labor intensity;

Protect downstream equipment: Effectively intercepts impurities, preventing contamination of pelletizers, dehydrators, and hoppers; reduces wear on cutting heads and screens, extending equipment lifespan.

III. Mainstream Granulation Applications

The dual-column screen changer suits most thermoplastic granulation lines, particularly for high-impurity content and high-continuity production scenarios:

Recycled Plastic Granulation: Granulation of PP/PE/ABS/PS recycled flakes (containing significant carbon black, metal, and sand residues; prone to screen clogging requiring frequent changes);

Modified Plastic Pelletizing: Glass-fiber reinforced / mineral-filled PP/PA/PBT pelletizing (contains glass fiber fragments and filler impurities, requiring precise filtration to prevent black spots on pellets);

Masterbatch / Functional Masterbatch Pelletizing: Pigment / additive-filled pelletizing (filters additive agglomerates and scorch to ensure uniform masterbatch coloration);

General-purpose plastic pelletizing: Virgin material pelletizing / Water gate material pelletizing (Filtering minor impurities to maintain particle grade);

Engineering plastic pelletizing: PC/PMMA/POM pelletizing (High demands on melt cleanliness and process stability; low-fluctuation screen changes suit high-end particle production).

Unsuitable Scenarios: Ultra-low capacity lab pelletizing lines (<50kg/h). For such applications, compact basket-type screen changers offer lower costs. Ultra-high-temperature specialty plastic pelletizing (e.g., PI/PPS requires custom dual-column screen changers with specialized materials).

IV. Optimization Recommendations for Pelletizing Production Lines

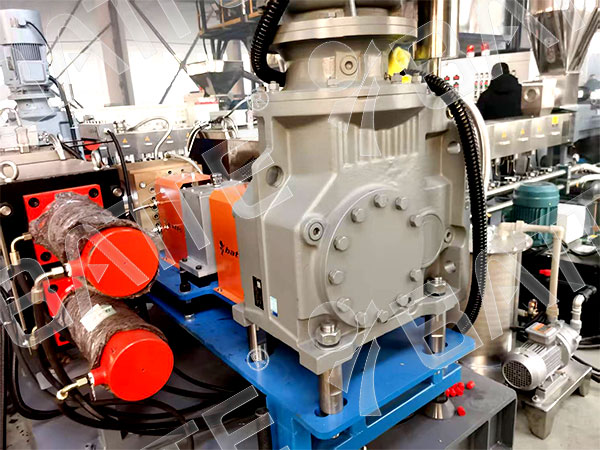

High-Capacity / High-End Pelletizing Lines:

Dual-column screen changers + melt metering pumps used in series. The melt pump first stabilizes pressure and meters the melt before it enters the screen changer for filtration. This further reduces pressure fluctuations during screen changes, ensuring particle size and weight accuracy while extending the service life of the screen changer filters.

Recycled Material Pelletizing Line: Install a pre-treatment system (magnetic separation for iron removal, vibrating screen for large particle impurities) upstream of the screen changer to reduce contaminants entering the system and decrease screen change frequency.

High-Temperature Engineering Plastic Pelletizing: Utilize dual-column screen changers made of high-temperature alloy materials (e.g., Inconel 625), equipped with high-temperature resistant ceramic heating rings. Channel surfaces undergo polishing treatment (Ra ≤ 0.8μm) to prevent melt retention and coking.

Automation Upgrade: Integrate the screen changer with the pelletizing line's central control system to automate screen change logging, pressure curve tracking, and temperature monitoring. This facilitates production traceability and process optimization.

The dual-column screen changer represents the optimal filtration solution for achieving continuous, high-capacity, and stable production in plastic pelletizing lines. It is indispensable, particularly for pelletizing recycled and modified materials. The core principles for its selection, configuration, and maintenance are matching extruder capacity, selecting screens suited to raw material impurities, and ensuring stable hydraulic system response. Proper configuration can significantly enhance production efficiency and product quality.

I can provide precise recommendations for the bore size, screen configuration, and supporting solutions of the dual-column screen changer based on your specific granulation materials (e.g., PP/PE recycled material, glass fiber modified material), extruder specifications, and production capacity requirements. Would you like me to assist?

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071