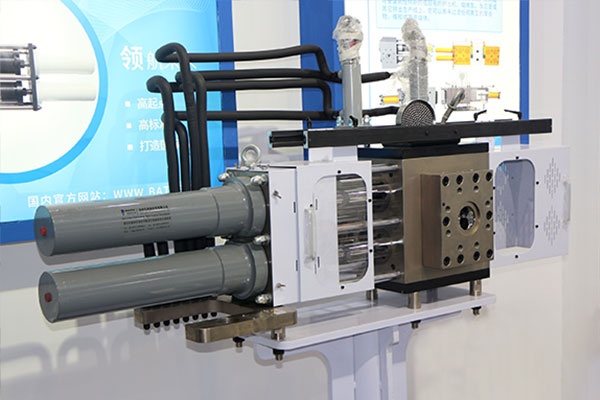

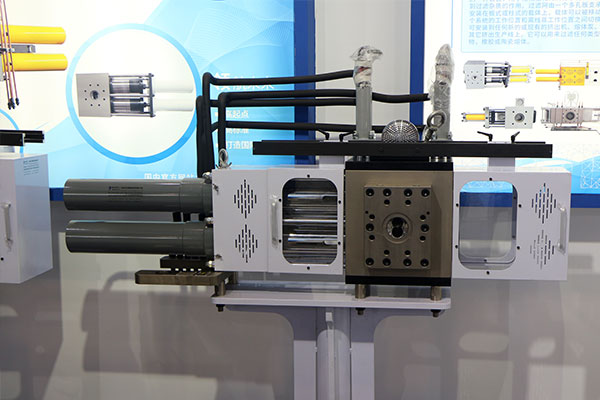

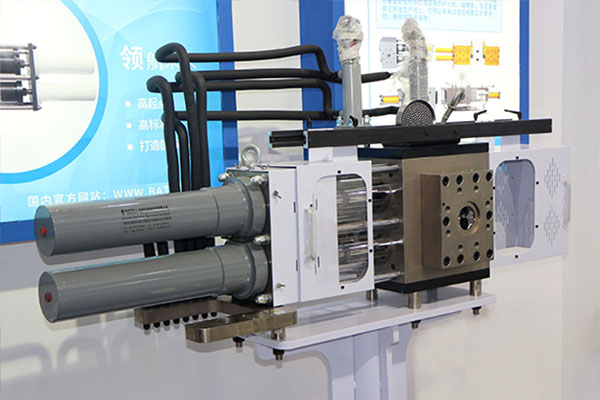

Hydraulic backflush automatic screen changer

The backflush screen changer is a continuous melt filtration device installed at the outlet of an extruder/melt pump. Its core feature is the addition of a reverse high-pressure flushing function to the non-stop screen changing process. This enables online removal of impurities from the filter screen, significantly extending its service life. It is particularly suitable for processing recycled plastics with high impurity content.

Core Structure and Principle

Typical Structure: Commonly features a dual-column, four-station design comprising the screen changer body, dual-plunger units (two stations per column), filter screens/perforated supports, backflush chambers with plungers, hydraulic system, and PLC control system.

Operational Flow

Normal Filtration: Melt passes through the working station screen, capturing contaminants like carbonized particles, metal shavings, and gels.

Differential Pressure Trigger: When the pressure differential before/after the screen reaches the set value (e.g., 8–10MPa), the system switches that station to offline status;

Backflushing: High-pressure melt/specialized medium reverses direction to impact the filter screen, stripping and discharging impurities;

Reset to Standby: After cleaning, the station returns to the standby queue without interrupting production.

Key Features

Continuous production with zero downtime during screen changes/backwashing and minimal pressure fluctuations, ensuring consistent product quality;

Screens are regenerable, significantly reducing consumable costs (up to 200+ cycles in certain conditions);

Rigid seal design withstands high temperatures and pressures, preventing melt leakage;

High automation enables unattended operation and remote monitoring;

Large filtration area, suitable for high-output extrusion lines (film blowing, cast film, pipe production, recycling pelletizing, etc.).

Applications

Extrusion lines for recycled plastic pelletizing and high-ratio recycled material blending;

High-precision products sensitive to pressure fluctuations (e.g., optical films, thin-walled pipes);

Continuous extrusion processes for chemical fiber spinning, sheet/plate production, cable sheathing, etc.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071