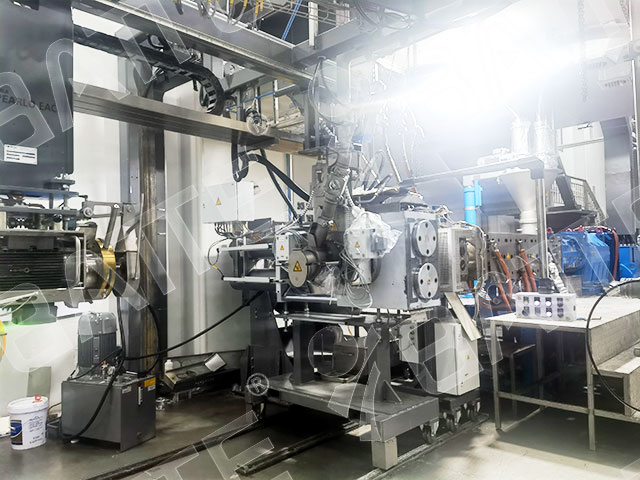

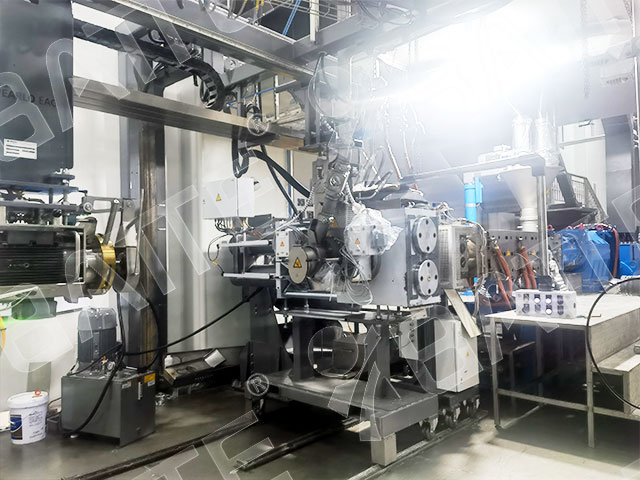

Double-column Screen Changer for Ultra-High Voltage Cable Extruder

The dual-column screen changer serves as the critical filtration equipment for ultra-high-voltage cable insulation/sheath extrusion. Its core value lies in providing continuous filtration without downtime, ensuring leak-proof high-pressure sealing, and maintaining stable melt pressure. It meets the stringent cleanliness and process stability requirements for insulating materials like XLPE, directly determining the voltage resistance and service life of the cable insulation layer.

Core Application Scenarios and Value

Ultra-high voltage cables (275kV–800kV) impose stringent requirements on insulation layer (e.g., cross-linked polyethylene XLPE) impurity control, thickness uniformity, and dielectric stability. The dual-column screen changer is primarily used for:

Insulation Layer Extrusion Filtration: Intercepts minute impurities (e.g., carbon black particles, gels, metal debris) in XLPE raw materials and recycled feedstock, preventing pinholes, bubbles, and breakdown points in the insulation layer. This ensures long-term insulation strength and operational reliability.

Sheath and filler cord extrusion: Enables continuous filtration of auxiliary materials like PE/PP sheaths and filler cords, preventing sheath damage or uneven filling caused by contaminants, thereby enhancing overall mechanical and protective properties of the cable.

Process Continuity and Energy Efficiency: Dual-column, dual-station design enables non-stop screen changes, eliminating insulation thickness fluctuations, cable breaks, and energy losses caused by downtime. Ideal for large-cross-section (e.g., 800mm²+) and high-volume production.

Selection and Application Guidelines

Matching Filtration Precision

Insulation Layer Extrusion: Recommended 80–120 mesh filters paired with porous plates create a damping effect, balancing impurity interception with melt homogenization to improve plasticization.

Sheath / Filler Cord: Opt for 40–80 mesh filters to balance filtration efficiency and pressure loss, meeting high-output demands.

Pressure Rating and Flow Rate Matching

System pressure must cover extruder backpressure (typically 15–25MPa). For ultra-high-pressure scenarios, select models rated ≥35MPa to prevent high-pressure leaks.

Calculate flow rate based on cable cross-section and output: For large cross-sections (1000mm²+), recommend ≥1000cm² filtration area to ensure stable melt velocity and uniform pressure.

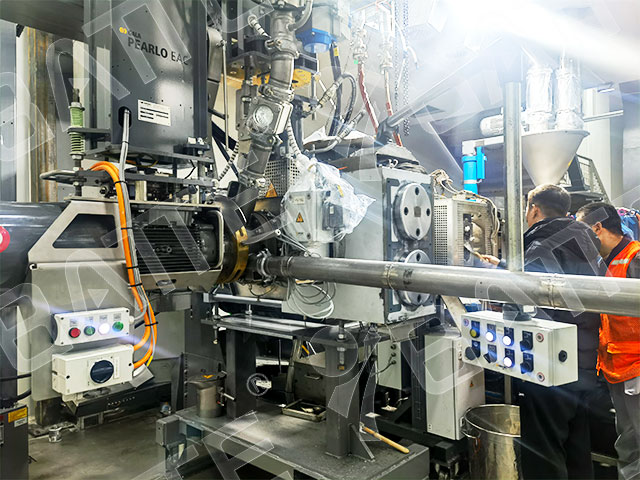

Installation and Control Integration

Installation Position: Between extruder and crosslinking die, positioned close to the die to minimize melt residence time and reduce degradation risk.

Control Integration: Interlock with extruder, melt pump, and pressure sensors to achieve closed-loop control: pressure warning → automatic screen change → charge and vent → blowdown, minimizing manual intervention.

Compatible with mainstream extrusion lines (e.g., Magner, Bruckner). Customizable to original screen changer dimensions, interface specifications, and hydraulic connections for seamless replacement and process compatibility.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071