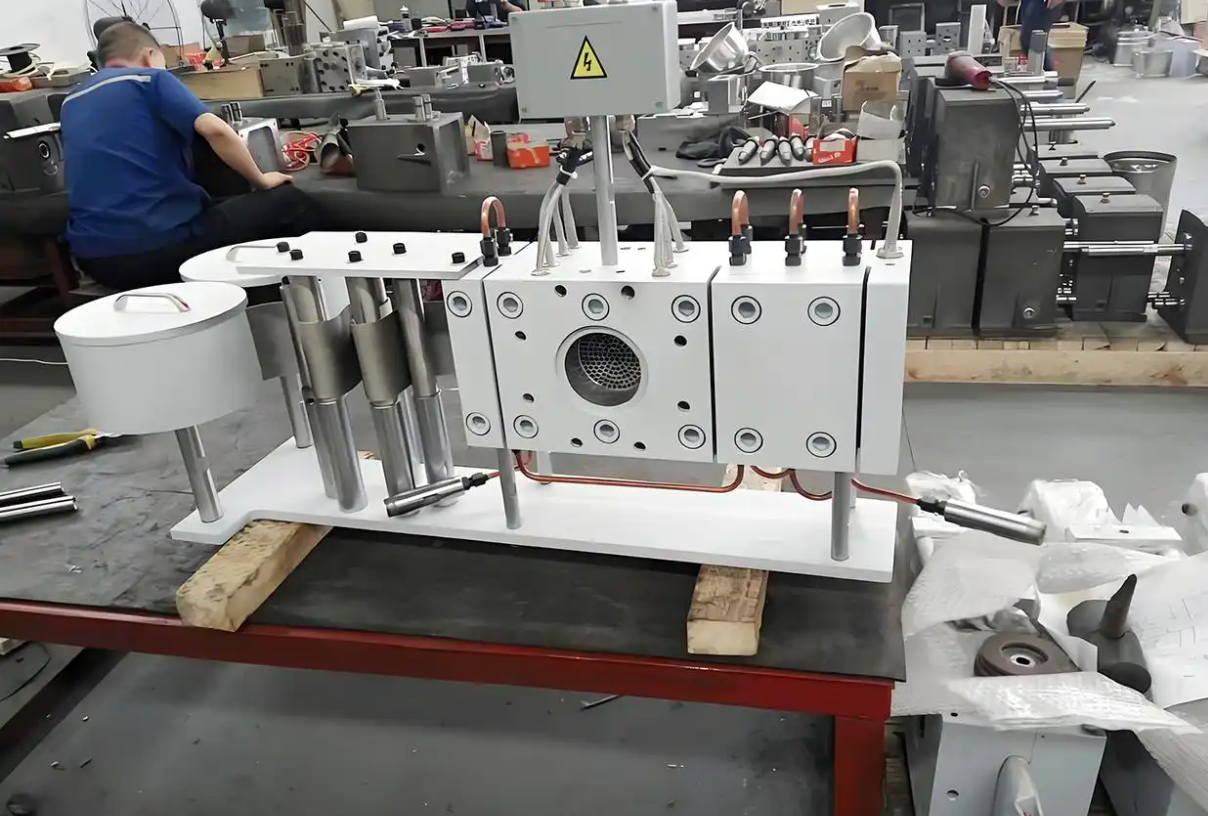

Automatic Screen Changer for Wire Drawing Machines

I. High Degree of Automation

Fully Automatic Operation: The automatic screen changer enables continuous, uninterrupted filter screen replacement without manual intervention, significantly reducing labor intensity and enhancing production efficiency. Intelligent Control: Through an advanced control system, the automatic screen changer initiates and terminates the screen-changing process based on preset pressure or time parameters, ensuring precise control.

II. Stable Material Flow

Fluctuation-Free Screen Change: During screen replacement, material flow and pressure remain stable, eliminating fluctuations caused by shutdowns in traditional methods. This ensures consistent product quality.

Continuous Production: Since no shutdown is required, continuous production is maintained, enhancing overall line efficiency.

III. Reduced Waste Generation

Precise Control: The automatic screen changer precisely regulates the movement speed and distance of the filter screen, preventing waste caused by improper screen movement.

Energy Efficiency & Environmental Protection: Reduced waste not only saves raw material costs but also helps lower energy consumption and minimize environmental pollution, aligning with green production principles.

IV. High Flexibility

Customizable Parameters: Users can freely set parameters such as screen travel distance and speed to adapt to varying production conditions.

Wide Applicability: Suitable for filament production of diverse polymer materials like nylon and polyester, offering strong versatility and flexibility.

V. Enhanced Product Quality

Superior Filtration: Utilizing high-quality filter materials, the automatic screen changer effectively removes impurities and particulates from the melt, improving product purity and quality.

Reduced Defects: Maintaining stable material flow and uninterrupted production during screen changes minimizes defects and scrap rates caused by screen replacement.

VI. Maintenance Convenience

Rational Structural Design: Typically featuring a modular design, the automatic screen changer facilitates disassembly and repair. Its internal structure is straightforward and easy to clean and maintain.

Reduced Downtime: The high degree of automation in the screen-changing process and ease of maintenance minimize equipment-related downtime, thereby improving overall production line utilization.

In summary, automatic screen changers for wire drawing machines demonstrate significant advantages in automation level, material flow stability, waste reduction, flexibility, product quality enhancement, and maintenance convenience. These benefits establish automatic screen changers as indispensable equipment in modern wire drawing production.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071