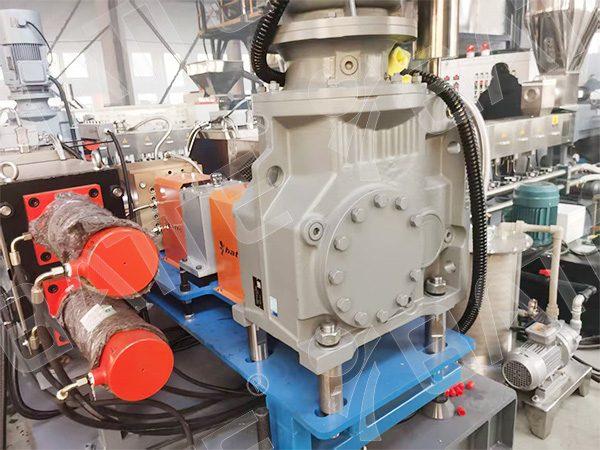

Dual-Column Screen Changer for HDPE Ceramic Powder Pelletizing Production Line

The dual-column screen changer serves as a critical melt filtration device in HDPE ceramic powder pelletizing production lines. Its primary function is to filter impurities, undispersed ceramic powder agglomerates, and carbonized material from the melt. This ensures the purity and uniformity of the pelletized product while maintaining stable, continuous operation of the production line.

Core Functions of the Dual-Column Screen Changer in This Production Line

Impurity Filtration

After HDPE and ceramic powder are blended and melted, impurities from the ceramic powder raw material, metal shavings from equipment wear, and small amounts of overheated decomposed plastic coke particles generated during processing may contaminate the melt. The dual-column screen changer intercepts these impurities via its filter screens, preventing their entry into subsequent pelletizing stages. This avoids die blockages and preserves particle appearance and performance.

Ceramic Powder Agglomerate Screening If ceramic powder disperses unevenly during blending, agglomerates may form. These agglomerates not only reduce the mechanical properties and filling uniformity of the pelletized product but may also cause defects in subsequent processing (e.g., injection molding, extrusion). The screen mesh of the changer can sift out some small-particle-size agglomerates, enhancing melt homogeneity.

Key Selection Criteria for HDPE Ceramic Powder Pelletizing

Filter Mesh Specification Selection

Determine mesh count based on ceramic powder particle size, filler ratio, and pellet product precision requirements. Multi-layer composite filters are generally recommended: coarse mesh (outer layer) intercepts large impurities, while fine mesh (inner layer) filters minute impurities and small agglomerates.

Note: Excessively high mesh counts increase melt flow resistance, elevating melt pressure and necessitating matching with the extrusion power of the production line.

Material Selection and Wear Resistance HDPE ceramic powder melt contains numerous hard ceramic particles, causing severe wear on the chamber, valve core, and seals of the screen changer. Therefore, melt-contacting components must be made of high-wear-resistant alloy materials (e.g., nitrided steel, hard alloy coatings). Seals should utilize high-temperature and wear-resistant materials like fluororubber or PTFE to extend equipment lifespan.

Temperature and Pressure Adaptation HDPE's melting temperature ranges from approximately 180–220°C. Screen changers require independent temperature control systems to maintain uniform cavity temperatures and prevent localized melt overheating and decomposition. Additionally, equipment must withstand high pressures during melt filtration (typically operating at 10–30 MPa) to ensure structural integrity and sealing performance.

Precautions for Application

Regular cleaning and maintenance are essential. The abrasive nature of ceramic powder accelerates screen clogging. Screen cleaning stations should be switched promptly based on changes in melt pressure. It is recommended to establish a pressure monitoring mechanism. When melt pressure exceeds the set threshold, immediately initiate the screen change procedure.

Compatibility with Extruders

The flow cross-sectional area of the screen changer must match the extruder's output capacity to prevent melt retention and overheating decomposition caused by insufficient flow area.

Screen Replacement Frequency

Replacement frequency depends on ceramic powder filling ratio (higher filling ratios cause faster screen clogging), raw material impurity content, and screen mesh count. Adjust based on actual production conditions.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071