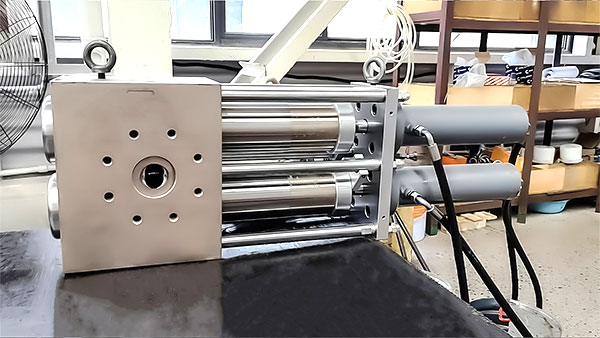

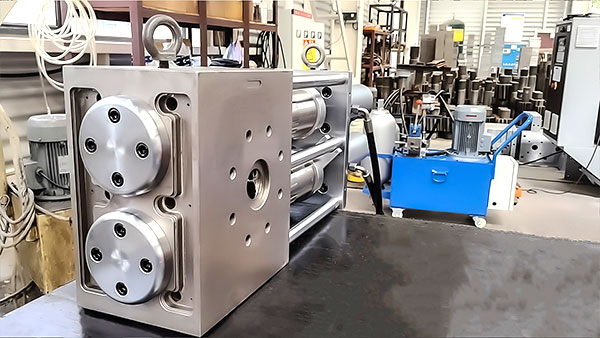

Dual-Column Screen Changer for PA12 Nylon Pipe Extrusion Production Line

The dual-column screen changer serves as the core equipment for continuous, non-stop filtration of melt impurities. Designed to meet the high-viscosity, high-temperature, and chemical corrosion resistance requirements of PA12 nylon pipe extrusion processes, it effectively enhances pipe surface finish and dimensional stability while reducing extrusion fluctuation risks. The following sections detail its compatibility analysis, technical parameter selection, application advantages, and operational maintenance essentials.

I. Core Requirements for Screen Changers in PA12 Nylon Pipe Extrusion

PA12 is a low-water-absorption nylon material with melt viscosity ranging from 1000 to 30000 mPa·s (typical processing temperature: 200-240°C). During pipe extrusion, the following conditions must be met:

Non-stop filtration: Prevents melt pressure fluctuations caused by screen changes, which can lead to uneven wall thickness and surface defects in pipes.

Temperature and Corrosion Resistance: Withstands PA12 processing temperatures without chemical reaction with the melt to prevent material contamination;

Low Pressure Drop: Minimizes melt residence time within the screen changer to prevent PA12 degradation at elevated temperatures;

Rapid Screen Change: Changeover time ≤3 seconds to reduce melt leakage risk and ensure continuous production line operation.

II. Application Advantages of Dual-Column Screen Changers in PA12 Production Lines

Continuous Production, Enhanced Efficiency

The dual-column structure enables uninterrupted screen changes by alternating between active and standby positions. Production lines can operate continuously for over 720 hours, reducing downtime for screen changes by over 80% compared to traditional plate-type screen changers, significantly boosting output.

Stable Melt Pressure for Consistent Tube Quality

Melt pressure fluctuation during switching remains ≤±0.5MPa, preventing defects like wall thickness deviation, bamboo-joint patterns, and surface pitting. This is particularly suitable for extruding precision PA12 nylon tubes (e.g., automotive fuel lines, pneumatic tubes).

Reduces PA12 degradation risk

Dead-zone-free flow channel design with melt residence time ≤5 seconds—far below PA12's high-temperature degradation threshold (residence >30 seconds at 240°C triggers degradation)—effectively safeguards material mechanical properties (tensile strength, elongation at break).

Adapted for High-Filled PA12 Systems

For glass-fiber reinforced and mineral-filled PA12 pipe production lines, the dual-column filter changes efficiently remove filler agglomerates and impurities. This prevents hard particles from scratching the screw and mold, extending equipment lifespan.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071