Plastic Underwater Pelletizing Double-Column Hydraulic Screen Changer

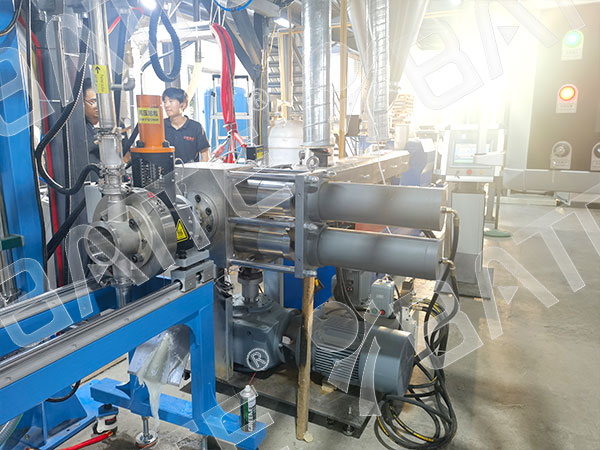

The Plastic Underwater Pelletizing Double-Column Hydraulic Screen Changer is a critical piece of equipment in the plastic processing industry for underwater pelletizing production lines. It primarily filters impurities from the melt to ensure product quality while enabling non-stop screen changes, thereby enhancing production efficiency.

Structural Features

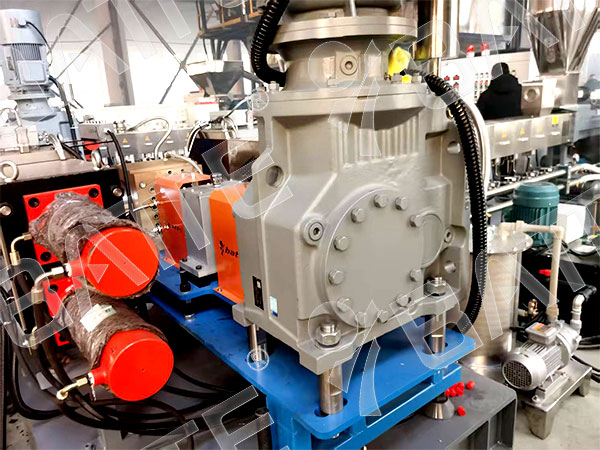

Dual-Piston Dual-Station Design: Features a symmetrical structure with dual pistons and dual stations. Two sets of filter screens operate simultaneously, significantly increasing filtration area and load capacity. During screen changes, the hydraulically driven piston moves the new screen station into the flow channel while the old screen station retracts for replacement, enabling non-stop operation.

Rigid Sealing Structure: Sealing surfaces utilize wear-resistant, high-temperature alloy materials. Hydraulic actuation ensures tight contact, effectively preventing flexible seal aging at high temperatures and deformation under high pressure. This prevents melt leakage and maintains stable melt pressure before and after filtration.

Optimized Flow Channel Design: The inner walls of the flow channels undergo precision polishing and feature a seamless, curved transition structure. This reduces melt flow resistance, prevents melt degradation due to stagnation within the channels, and ensures material purity.

Feed and venting structure: Utilizing a “progressive filling + vent hole design,” when a new filter enters the flow channel, melt is slowly introduced to expel air through vent holes before fully sealing the channel. This prevents defects like bubbles and pinholes caused by trapped gas.

Removable Orifice Plate Structure: The orifice plate features a removable design for easy material cleanup and equipment maintenance, reducing operator workload and enhancing maintenance efficiency.

Working Principle

The dual-column hydraulic screen changer employs a dual-column, dual-flow-channel design with internal heating for rapid and uniform temperature distribution. During normal production, both filter screens operate simultaneously. When screen replacement is required, one screen continues operation while the other is retracted from the flow channel via hydraulic drive for replacement. Concurrently, the material feed and venting devices—controlled automatically or manually—thoroughly evacuate air from the flow channel, enabling non-stop screen changes without material leakage or flow interruption.

Technical Parameters

Operating Temperature: Typically ≤350°C, meeting processing temperature requirements for most plastics and chemical melts.

Working Pressure: ≤50MPa, capable of handling high-pressure conditions during processing of high-viscosity melts.

Pressure Differential: ≤20MPa, effectively controlling pressure loss within the equipment to ensure stable melt flow.

Applicable Melt Viscosity: Typically 100~40000Pa・s, covering low to medium-high viscosity melts.

Heating Method: Supports both electric heating and thermal fluid heating modes, allowing flexible selection based on production requirements.

Application Scope

Widely used in plastic underwater pelletizing production, as well as in demanding applications requiring continuous production, such as plastic pipes, sheets, films, cast films, and chemical fiber spinning.

Optional Configurations

Highly Corrosion-Resistant Material Solution: Customized high-corrosion-resistant material options available for highly corrosive conditions, extending equipment service life.

Moving Installation Cart: Integrates the hydraulic station and control system onto a mobile cart, facilitating flexible equipment movement within the workshop and on-site maintenance.

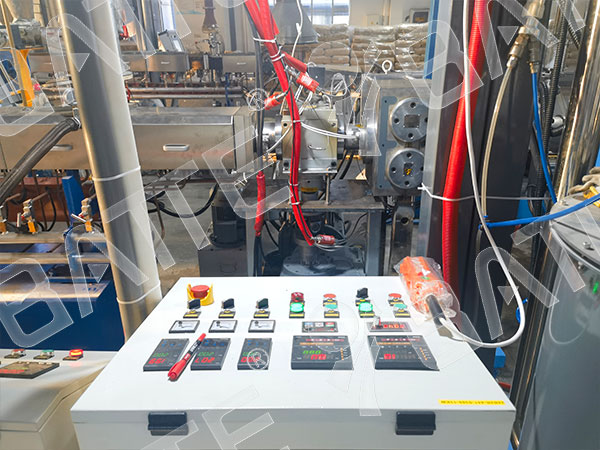

Automatic Control System: Optional automatic control system featuring integrated PLC and HMI. The human-machine interface enables equipment parameter setting, operational status monitoring, screen changing operations, and more, ensuring simple and convenient operation.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071