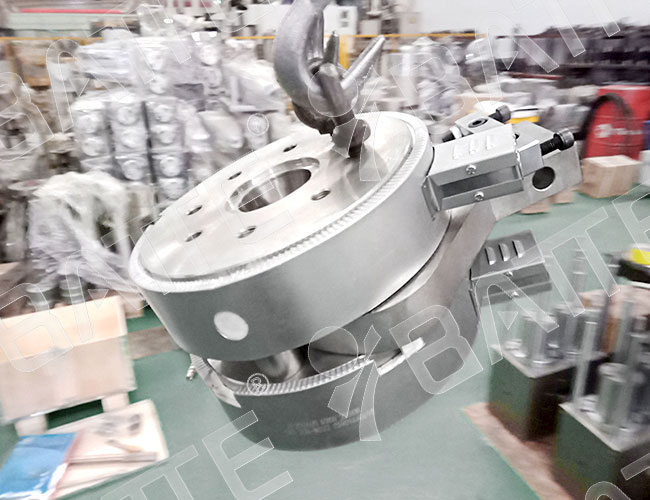

Plastic Film Blowing Manual Screen Changer

The manual screen changer for film blowing is a dual-station manual filtration switching device installed between the film extruder and the die head. Its core function is to filter melt impurities and stabilize flow channel pressure. Designed for small to medium-scale film blowing production lines, it achieves stable filtration and convenient maintenance at a low cost. It intercepts impurities (such as carbonized material, metal shavings, and gel spots) in film-blowing raw materials like PE, PP, and PVC, preventing die blockages, film holes, or crystalline spots. This ensures uniform film thickness and superior surface quality.

Working Principle of Manual Screen Changers for Film Blowing: Manual screen changers typically feature two filtration stations. When a filter accumulates contaminants requiring replacement, the operator manually moves the handle after slowing down or stopping the machine. This action removes the contaminated filtration station from the main unit while simultaneously positioning the clean filtration station into the operational position.

Advantages

Low Cost: Significantly lower procurement and maintenance expenses compared to automatic/hydraulic screen changers, with no complex electrical or hydraulic systems.

Simple Operation & Maintenance: Requires no specialized training; routine tasks involve only screen replacement and seal inspection, with minimal downtime.

Compact Design: Requires minimal installation space, ideal for space-constrained small-to-medium production lines with minimal retrofitting.

Reliable Sealing: Compensated seal design adapts to common film blowing conditions with high versatility.

Limitations

Requires shutdown for screen changes, interrupting production. Suitable for low-frequency screen changes (≤1 time/day) in small-to-medium batch production.

Manual operation is labor-intensive for large-size screen changers and slower than automatic models.

Suitable Applications

Small-to-medium film blowing plants, pilot production lines, and lines with low recycled material ratios.

Cost-sensitive PE/PP film production with limited space and infrequent screen changes.

This design enables operators to perform manual screen changes without external control systems, offering both user-friendly operation and significant filtration efficiency. It is widely adopted in film blowing production lines to ensure process continuity and product quality.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071