Sector-Type Rotary Screen Changer

In industrial production, particularly in fields such as plastic extrusion and chemical fiber spinning, melt filtration is a critical step in ensuring product quality. As a highly efficient, continuous filtration device, the sector-type rotary screen changer has gained popularity within the industry in recent years due to its unique structural design and outstanding performance. This screen changer achieves non-stop screen changes through its innovative rotating fan-shaped structure, significantly boosting production efficiency while reducing energy consumption and scrap rates. It has revolutionized modern industrial production.

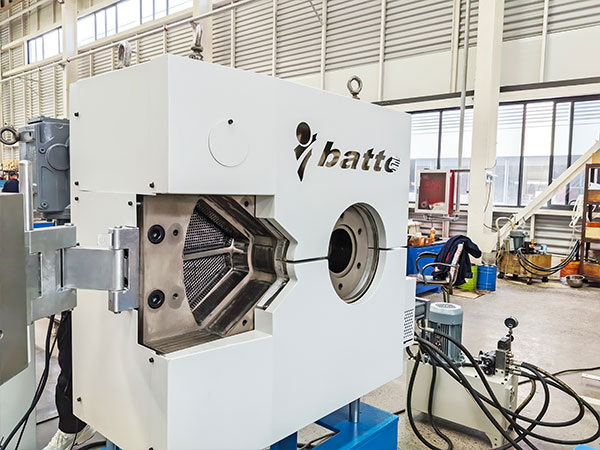

The core design philosophy of the fan-shaped rotary screen changer lies in its unique fan-shaped filter units and rotating switching mechanism. The equipment primarily consists of four major components: the feed system, the filtration system, the switching mechanism, and the control system. The feed system is responsible for evenly distributing the melt to each filter unit; the filtration system comprises multiple fan-shaped filter screens arranged radially, capable of rotating around a central axis; The switching mechanism rotates the filter set as needed, positioning the clean filter into the working position; the control system precisely manages the entire screen-changing process. The greatest advantage of this design is enabling true continuous production. When one filter set becomes clogged, rotating it a specific angle switches to a new filter set. The entire process takes only seconds with minimal pressure fluctuation, typically controlled within 3%. This is crucial for maintaining consistent product quality.

Compared to traditional screen changers, the sector-rotating design demonstrates significant advantages in multiple aspects. First is its continuous operation capability. Traditional plunger-type changers require shutdown during screen changes, impacting production efficiency while causing material waste and energy loss. The sector-rotating design completely eliminates this issue, enabling true 24/7 uninterrupted production. Second, it offers a larger filtration area. Utilizing multiple sets of fan-shaped filter screens, its effective filtration area is typically 3-5 times that of traditional changers. This translates to longer service cycles and reduced filter change frequency. Thirdly, it maintains excellent pressure stability. During rotation, the melt flow path remains unobstructed, resulting in minimal pressure fluctuations—critical for producing high-quality products. Additionally, this design incorporates self-cleaning functionality: when a filter group rotates out of position, residual melt automatically sheds under gravity, reducing manual cleaning requirements.

Proper installation and operation of the rotary sector-type filter changer must adhere to specifications. During installation, ensure inlet and outlet piping alignment to prevent stress concentration. Prior to initial operation, perform thorough preheating with gradual temperature increases. During routine operation, regularly inspect seals and verify rotational mechanism flexibility. Establish a comprehensive maintenance regimen including periodic lubrication and seal replacement. Crucially, thorough cleaning is mandatory when switching processed materials to prevent cross-contamination. Adopting sound operational practices significantly extends equipment lifespan and enhances economic efficiency.

Overall, the sector-type rotary screen changer represents the cutting edge of melt filtration technology. Its innovative design philosophy and outstanding performance are delivering significant quality improvements and efficiency gains for the polymer materials processing industry, including plastics and chemical fibers. With continuous technological advancement and expanding applications, this equipment will undoubtedly play a vital role in broader fields, providing robust support for high-quality development in manufacturing. For manufacturers, timely adoption of this advanced equipment is not only an effective means to enhance competitiveness but also an inevitable choice for industrial upgrading.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071