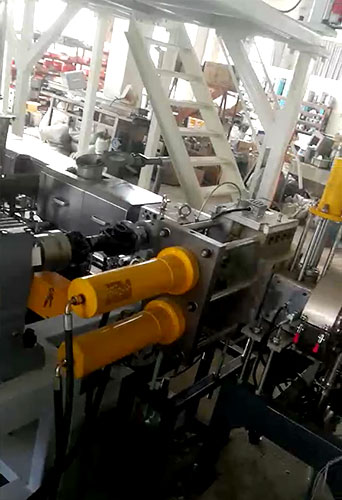

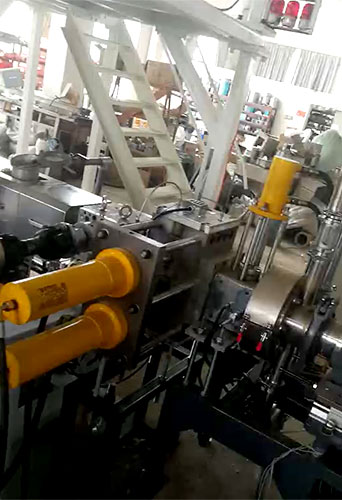

Double-Plate Hydraulic Screen Changer for PMMA Acrylic Profile Extrusion Production Lines

The double-plate hydraulic screen changer serves as a critical component in PMMA acrylic profile extrusion production lines. Tailored to the properties of PMMA material, it addresses core production challenges such as impurity filtration and continuous operation, significantly enhancing production line efficiency and product quality.

Core Function: Adapted to PMMA Profile Production Requirements

Precision Filtration Ensures Appearance and Performance: Impurities or unmelted particles in PMMA acrylic raw material can cause surface defects like scratches and spots on extruded profiles, while also compromising structural integrity. The dual-plate hydraulic screen changer achieves filtration precision of 50–300 microns. Its dual-plate design doubles the filtration area, efficiently intercepting these contaminants. Simultaneously, its optimized flow channel design reduces melt shear stress, promoting more uniform PMMA melt plasticization. This results in extruded profiles with higher surface finish and more consistent internal texture.

Non-Stop Screen Changes Minimize Material Loss: As a heat-sensitive material, PMMA undergoes thermal degradation when left idle during screen changes, leading to material waste and potential contamination of subsequent batches. This screen changer employs dual-station alternating operation. When one station's filter becomes clogged, the hydraulic system switches to the other station within seconds, enabling uninterrupted production during screen changes. This feature prevents PMMA degradation caused by downtime. Typically, a single production line saves over 200 hours of downtime annually, significantly increasing effective production time.

Stable process parameters reduce defect rates: Its accumulator-equipped hydraulic station minimizes pressure fluctuations during screen changes. Sealing technology withstands the high-temperature, high-pressure conditions of PMMA extrusion, eliminating melt leakage. This stability prevents abrupt changes in temperature and pressure fields caused by conventional screen changes, effectively avoiding issues like uneven wall thickness and deformation in extruded profiles, significantly lowering defect rates.

In PMMA acrylic profile extrusion lines, it is typically installed between the single-screw extruder and the metering pump. This placement ensures the plasticized PMMA melt undergoes filtration before entering the subsequent die extrusion stage. Combined with pressure feedback from the metering pump, it further enhances profile dimensional accuracy. Its flexible flange design allows customization to match extruder models within the production line, ensuring strong adaptability.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071