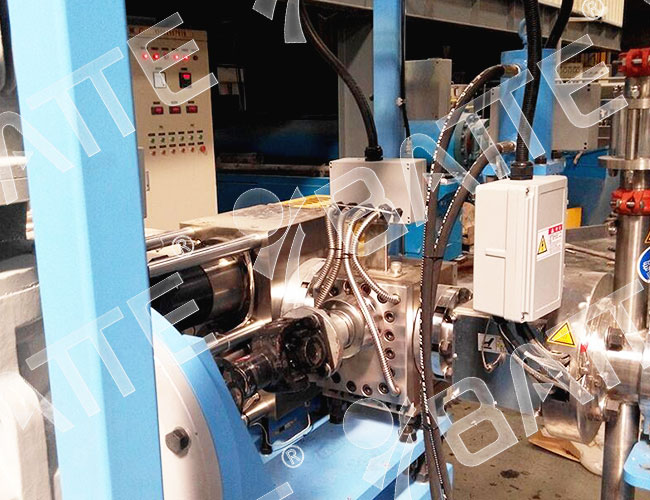

PU/TPU granulation, a melt pump + automatic screen changer

For PU (Polyurethane) and TPU (Thermoplastic Polyurethane) plastic granulation processes, the melt pump and screen changer system plays a critical role in ensuring stable extrusion, filtering impurities, and improving product quality.

Melt Pump:

Acts as a positive displacement device to stabilize melt pressure and flow rate, eliminating fluctuations caused by extruder screw design, temperature control, or feed interruptions.

Reduces backpressure on the extruder, lowering melt temperature and energy consumption while increasing output (typically by 10-30%).

Enables precise metering (flow rate proportional to pump speed with <1% deviation), crucial for high-value materials like TPU where dimensional accuracy is critical.

Supports multi-extruder configurations, allowing multiple small extruders to feed a single large melt pump for cost-effective production of wide-format products (e.g., films, sheets).

Screen Changer:

Filters impurities (e.g., gel particles, carbonized material) to prevent defects in the final granules.

Automatic/continuous screen changers (e.g., double-column hydraulic or rotary types) allow uninterrupted production during filter replacement, minimizing waste and downtime.

Dual-flow channel design with internal heating ensures rapid, uniform temperature rise, preventing melt degradation during screen changes.

Recommended System Configuration

For Small-Scale Production (e.g., Lab or Custom Compounding):

Single-screw extruder + Gear pump + Manual screen changer

Example: 35mm single-screw extruder + 10cc/rev melt pump + 150mm² manual screen changer.

For High-Volume Production (e.g., Industrial TPU Granulation):

Twin-screw extruder + High-torque melt pump + Automatic double-column screen changer

Example: 55mm co-rotating twin-screw extruder + 50cc/rev melt pump + 300mm² hydraulic screen changer with 20μm filtration.

For PU/TPU granulation, a melt pump + automatic screen changer system is highly recommended to achieve stable production, high product quality, and cost efficiency. Suppliers like Zhengzhou Batte offer integrated solutions tailored to TPU’s unique processing requirements (e.g., high viscosity, abrasive fillers). For budget-conscious setups, manual screen changers can be used initially, with upgrades to automatic models as production scales up.