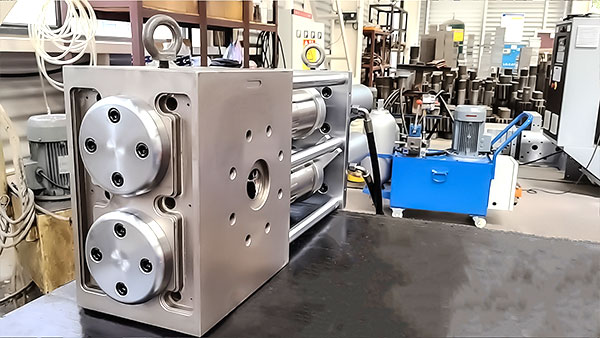

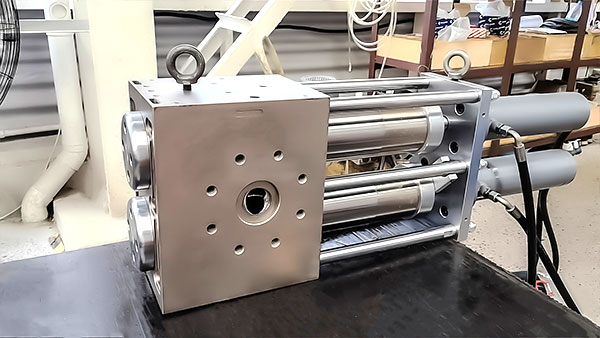

Dual-Column Screen Changer for Cable Filler Rope Production Lines

Core Advantages of the Dual-Column Screen Changer

Uninterrupted Continuous Production: Featuring a dual-column, dual-station design, it enables screen changes without stopping the machine, eliminating production downtime caused by screen changes and significantly boosting production efficiency.

Stable Pressure for Process Control: During screen changes, the backup screen continues operation, minimizing fluctuations in material flow pressure. This ensures stable extrusion processes and contributes to uniform, controllable product quality.

High-Efficiency Filtration for Enhanced Quality: The dual-column structure expands filtration area, precisely intercepting impurities in raw materials to effectively improve the quality of finished cable filling ropes.

Robust Durability for High-Pressure Resistance: Constructed from high-grade alloy steel with nitriding treatment, the main body offers a stable structure and strong load-bearing capacity. It is suitable for high-pressure working environments and boasts a long service life.

Simplified Operation and Maintenance: Highly automated screen-changing process with intuitive operation reduces labor intensity and lowers maintenance costs.

Application Areas of Dual-Column Screen Changer

Primarily used in cable filler rope production lines, compatible with extrusion processes for various filler rope materials including PE and PP. Especially suited for large-scale cable filler rope manufacturing demanding continuous production, product purity, and process stability.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071