BATTE double column screen changer replaces Maag screen changer

Replacing Maag screen changers with Batte double-column screen changers in ultra-high-voltage cable material production lines delivers core value through non-stop screen changes for continuous operation, low pressure fluctuations for stable processes, large filtration area for cost reduction, and high-pressure/high-temperature resistance for demanding conditions. Additionally, it offers short retrofit cycles and significant overall benefits. The following details compatibility, replacement advantages, implementation key points, and precautions.

Core Replacement Advantages

Enhanced Production Efficiency: Non-stop screen changes prevent material interruptions and speed reductions, boosting efficiency by 30%–50%. Minimal pressure fluctuations during changes ensure uniform insulation thickness and performance in cable compounds.

Reduced Operating Costs: Large-area screens extend filtration cycles, lowering screen change frequency by 30%–50% and saving on screen consumables and labor. The main unit lifespan exceeds 5 years, extending maintenance intervals to 3 months.

Enhanced Process Stability: Hydraulic system precisely controls cylinder movement, limiting melt pressure fluctuations to ≤±5%. This accommodates the process sensitivity of ultra-high-voltage cable materials, reducing defective output.

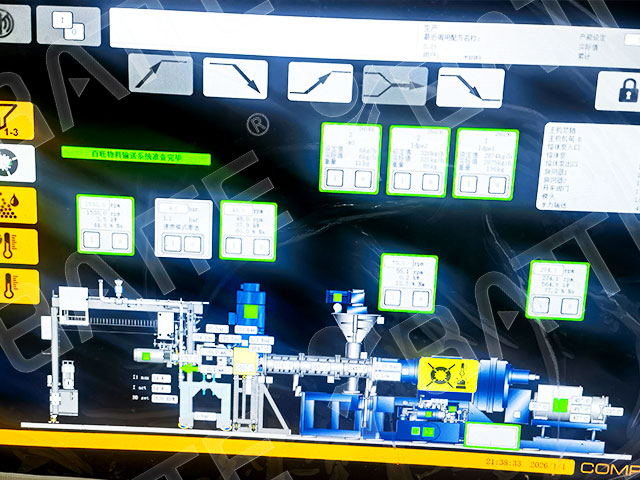

High Retrofit Flexibility: Modular design adapts to existing extruder interfaces, enabling short retrofit cycles without major production line layout changes. Supports PLC automation integration into production control systems for automated screen changes and fault alerts.

Key Implementation Points for Replacement

Preliminary Assessment

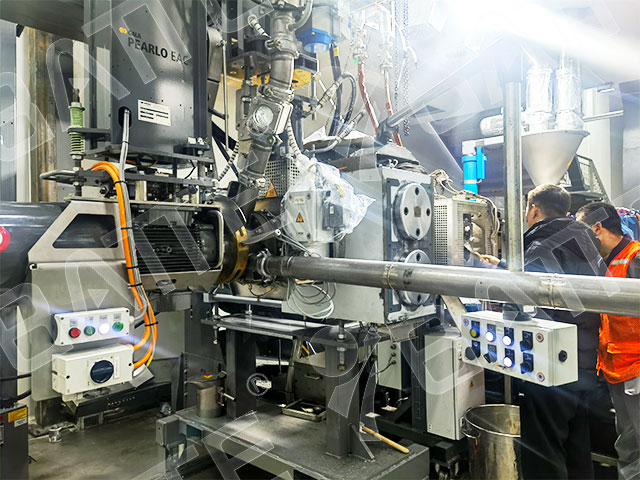

Confirm existing extruder model, output capacity, melt pressure/temperature, and screen specifications to match the corresponding Batte model (e.g., dual-column dual-station/four-station backflush models).

Verify installation dimensions (flanges, bore diameter, center distance). Custom adapter flanges may be required to ensure seamless integration.

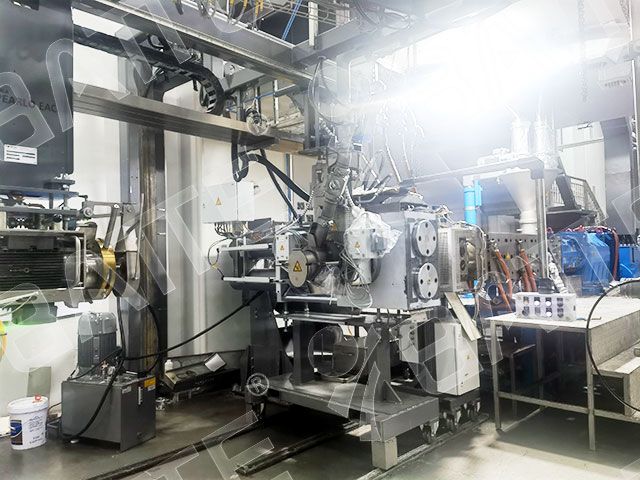

Modification Steps

Shut down equipment, remove MAG screen changer and connecting piping, clean residual melt.

Install BATTE dual-column screen changer, calibrate center alignment and leveling, secure flanges, connect to hydraulic station and heating system.

Commissioning: Set screen change differential pressure (0.5–1.2MPa), hydraulic pressure, and temperature parameters. Conduct no-load screen change testing to verify no leakage or jamming.

Material Trial Run: Gradually increase production capacity while monitoring pressure fluctuations and filtration efficiency; optimize parameters until stable operation is achieved.

Key Supporting Adjustments

Hydraulic Station: Match with a motor rated at 11kW or higher to ensure sufficient screen-changing power; configure accumulators to enhance screen-changing response speed.

Temperature Control: Integrate internal heating devices for precise temperature regulation, reducing energy consumption and temperature fluctuations.

Control System: Integrate with extruder PLC for automatic screen change triggering, data logging, and remote monitoring.

Precautions

Sealing and Leak Prevention: Ensure clean sealing surfaces and uniform bolt tightening during installation. Employ pressure-activated sealing technology under high-pressure conditions to prevent melt leakage.

Screen Selection: For ultra-high-voltage cable compounds, recommend 40–100 mesh multi-layer composite screens balancing filtration precision and flow rate to avoid excessive pressure.

Maintenance Protocol: Periodically inspect hydraulic oil cleanliness and seal wear; conduct comprehensive maintenance every 3 months. Record differential pressure and replacement intervals after screen changes to optimize replacement frequency.

Spare Parts Stockpile: Maintain inventory of spare screens, seal rings, hydraulic filter elements, and other wear parts to minimize downtime during failures.

ould you like me to provide corresponding Batte double-column filter changer model recommendations, installation dimension lists, and retrofit schedules based on your extruder model, production capacity, and melt pressure/temperature?

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071