Dual-Column Hydraulic Screen Changer for PE Modified Masterbatch

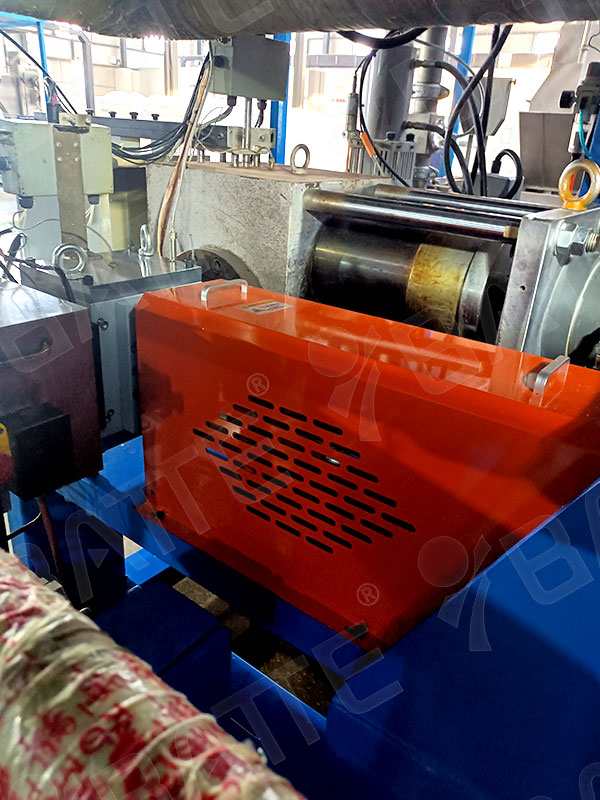

The Dual-Column Hydraulic Screen Changer for PE Modified Masterbatch features a dual-channel, dual-station design enabling non-stop online screen changes. Its core value lies in efficient impurity filtration, stable melt pressure, and ensuring continuous masterbatch production with uniform performance. It accommodates HDPE/LDPE/LLDPE modification scenarios including filled, color masterbatch, and functional masterbatch applications, particularly suited for high-filling (≤60%) and high-capacity production conditions.

Core Selection Parameters (PE Modified Masterbatch Compatibility)

|

Parameter |

Recommended Range |

Selection Key Points |

|

Operating Temperature |

≤350℃ |

PE degradation temperature approx. 300℃, reserve 50℃ safety margin, temperature control accuracy ±1℃, electric heating / thermal fluid heating |

|

Operating Pressure |

Inlet: 0.5~3 MPa; Outlet ≤35 MPa;

Max. differential pressure ≤20 MPa |

Match extruder → screen changer → melt pump → die head pressure loss, reserve 10~20% margin |

|

Filter Area |

Circular Φ50~Φ150 mm; Square/

Curved matched to production capacity |

Larger capacity and higher impurity levels require larger filter area to extend screen change cycles |

|

Mesh Count |

80–150 mesh (standard masterbatch);

150–200 mesh (color masterbatch / functional masterbatch) |

Prevents leakage of fillers (calcium carbonate, glass fiber) while balancing throughput and filtration efficiency |

|

Material & Sealing |

Main body /

Cylinder: H13 nitrided steel or

duplex stainless steel; Rigid face seal |

Wear-resistant and corrosion-resistant, suitable for high-filler wear conditions, prevents melt leakage |

|

Hydraulic System |

Pressure: 10~20 MPa,

Response time ≤0.5 s |

Rapid cylinder switching, maintains pressure fluctuation within ±5% during screen changes |

Key Structure, Functionality, and Installation Considerations

Core Structure and Advantages

Dual-channel dual-station: Alternating operation of dual columns enables simultaneous production and screen changing without downtime or material interruption, significantly boosting output.

Feed material venting system: Pre-filling and venting before screen change reduces bubbles and pressure fluctuations, ensuring stable masterbatch quality.

Optimized Flow Path: Eliminates dead zones and stagnant flow, minimizing PE melt degradation and retention risks.

Installation and Compatibility

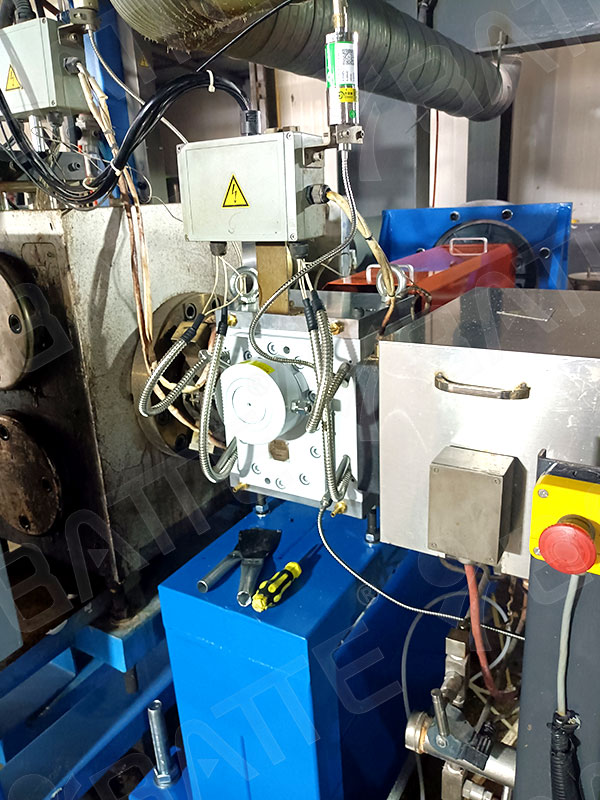

Positioning: Extruder → Screen Changer → Melt Pump → Die. Prioritize installing a coarse pre-filter (80–100 mesh) before the pump inlet to prevent large impurities from causing jams.

Connection: Flange sealing with mirror-polished flow channel inner walls (Ra ≤ 0.4 μm) to reduce melt resistance and shear heat.

Control: PLC+HMI automated control system supporting differential pressure alarms, automatic screen changes, and compatibility with loss-in-weight feeding closed-loop systems.

Maintenance and Common Faults

Screen Change Interval: Set based on differential pressure (recommended ≤2 MPa) or production capacity; shorten intervals for high-filler/recycled materials.

Shutdown Maintenance: Clean machine with clean PE to prevent filler residue from wearing seal surfaces.

Common Faults: Significant pressure fluctuations (check venting/screen clogging), leakage (replace seals), switching hesitation (inspect hydraulic system or foreign objects).

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071