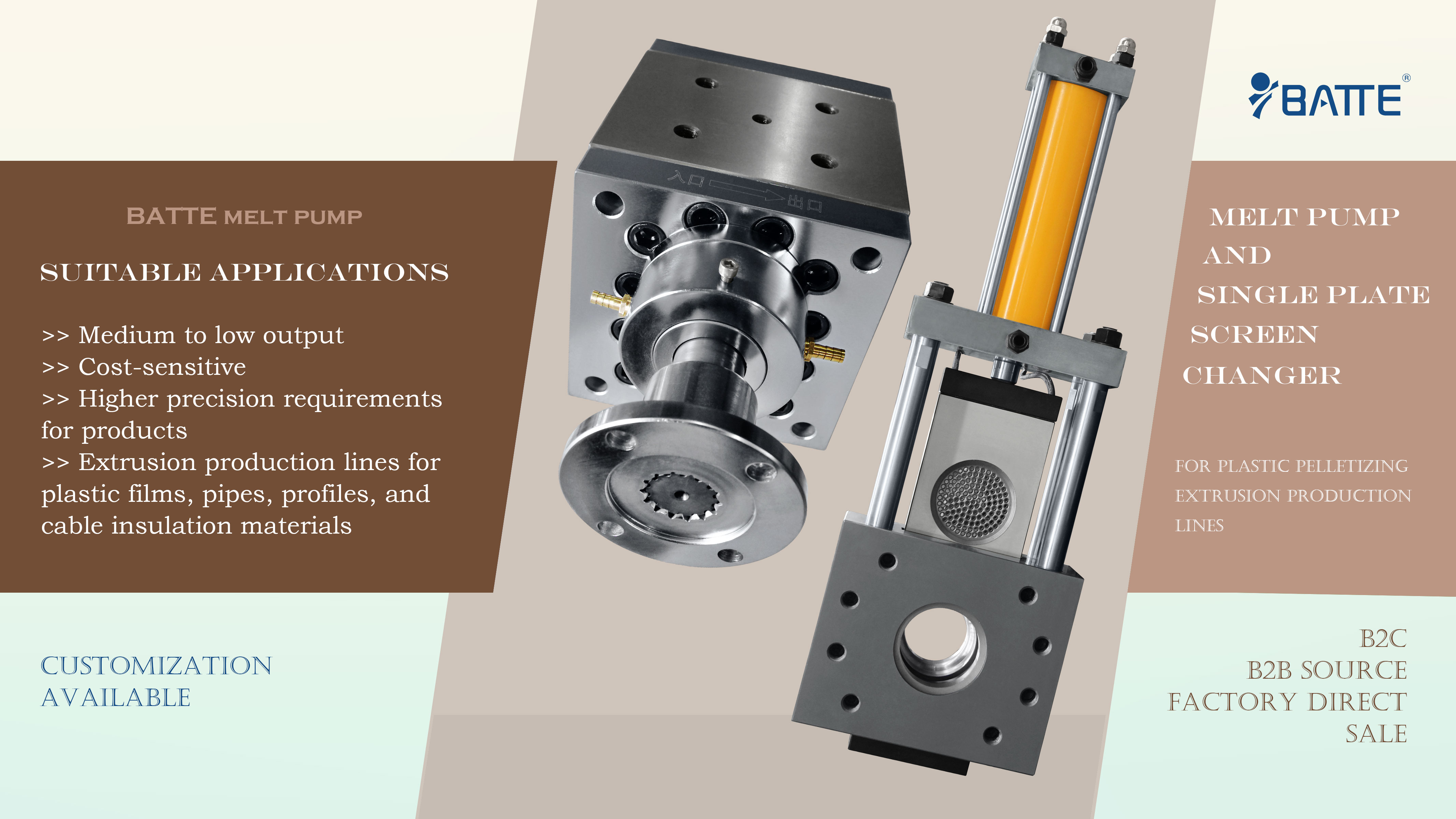

Melt pump and single plate screen changer For Plastic Pelletizing Extrusion Production Lines

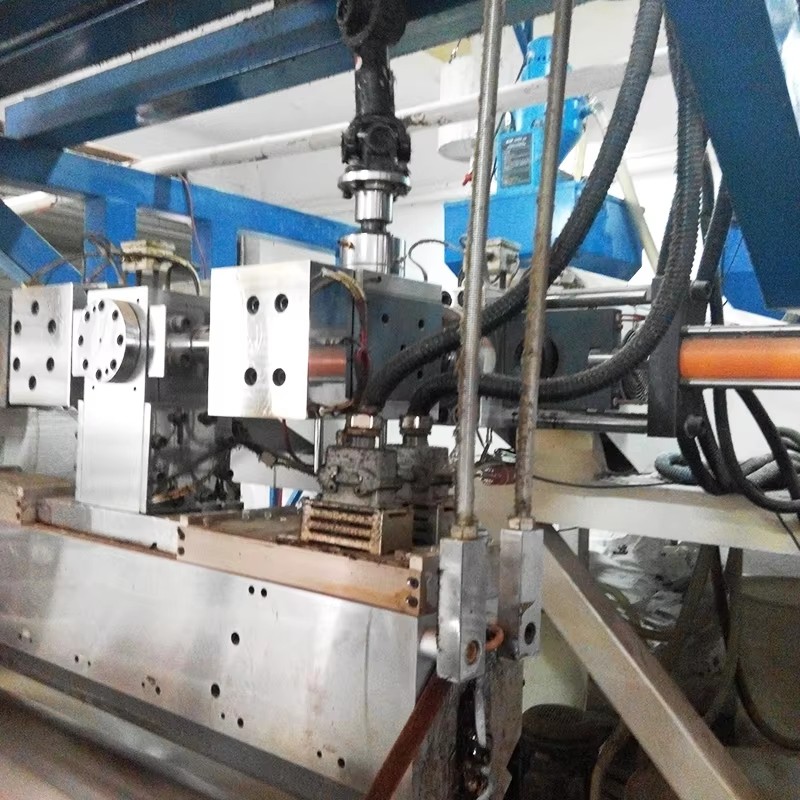

The melt pump, when paired with a single-plate screen changer, forms a core combination solution in plastic extrusion production lines. This pairing stabilizes pressure, enhances product precision, and ensures continuous production. Their complementary advantages significantly optimize the overall performance of the extrusion process.

Core Advantages of the Melt Pump

The melt pump is a positive displacement conveying device installed between the extruder and the die. Its core functions are pressure stabilization, flow regulation, and quality enhancement.

Precise and Stable Extrusion Pressure and Flow

The melt flow conveyed by the extruder screw is susceptible to fluctuations in temperature, material viscosity, and screw speed. The melt pump forcibly stabilizes melt delivery, controlling pressure variations within ±1%. This substantially improves product dimensional accuracy (e.g., film thickness uniformity, profile cross-section consistency).

Reducing Extruder Load for Energy Savings

The melt pump handles high-pressure build-up at the die inlet, lowering extruder screw backpressure and reducing wear on the screw and barrel. This also conserves electrical power consumption (typically achieving 10%–30% energy savings).

Expands material compatibility

For high-viscosity and heat-sensitive materials (e.g., PC, PMMA, engineering plastics), the melt pump's smooth delivery reduces residence time in the barrel, preventing degradation. It also accommodates extruding filled materials (e.g., glass-fiber reinforced plastics) and recycled materials.

Enhance production line automation

Interoperates with pressure sensors and frequency converters to achieve closed-loop control, automatically adjusting pump speed to compensate for process fluctuations and reduce manual intervention.

Core advantages of single-plate screen changers

Single-plate screen changers are critical equipment for filtering melt impurities and ensuring melt cleanliness. Their relatively simple structure makes them suitable for small-to-medium production volume extrusion lines.

Efficient Impurity Filtration for Enhanced Product Quality

Effectively filters char particles, mechanical impurities, broken glass fibers, and foreign objects in recycled materials. Prevents mold clogging and surface defects (e.g., black spots, streaks) caused by contaminants, particularly suitable for products demanding high surface quality like films, pipes, and cable compounds.

Compact design with easy operation and maintenance

The single-plate screen changer features a small footprint, lightweight construction, and minimal installation space requirements. Screen changes can be performed quickly (some manual models achieve screen changes in <10 seconds), and the low-cost screens make it suitable for small-to-medium batch production scenarios.

Low pressure loss, compatible with medium-to-low viscosity materials

The single-plate structure offers lower flow resistance than multi-plate changers, resulting in minimal pressure loss and reduced energy consumption. It is particularly suitable for extruding medium-to-low viscosity general-purpose plastics like PE and PP.

Significant cost advantages

Compared to dual-plate and continuous changers, single-plate changers feature lower procurement and maintenance costs, offering high cost-effectiveness for small-to-medium enterprise production lines.

Synergistic Advantages of Combined Use

Ensures Continuous, Stable Production

While single-plate changers may cause brief pressure fluctuations during screen changes, melt pumps absorb these variations to maintain stable pressure at the die inlet. This prevents dimensional deviations or material breaks during screen changes, achieving both “non-stop screen changes” and “stable extrusion.”

Enhanced Filtration Efficiency and Product Precision

The melt pump's pressure stabilization ensures uniform melt flow through the screen changer's filter mesh, delivering consistent filtration performance. Simultaneously, the clean, filtered melt is precisely conveyed by the melt pump, concurrently improving both the intrinsic quality and surface precision of the final product.

Extended Equipment Lifespan

Hard contaminants filtered out by the screen changer prevent entry into the melt pump, reducing wear on pump gears and bearings. The melt pump's flow stabilization also lowers operating pressure on the screen changer, extending the lifespan of seals and filter screens.

This combination is particularly suitable for extrusion scenarios with medium to low output, cost sensitivity, and high precision requirements, such as the production of general-purpose plastic films, pipes, profiles, cable insulation materials, and recycled material extrusion lines.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071