Solve the problem of leakage from the screen changer

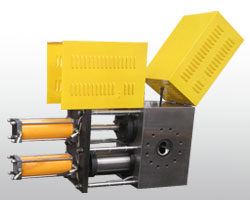

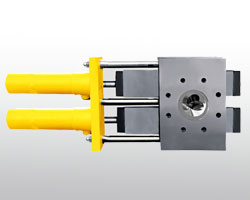

The screen changer is usually installed on the head of the machine. The exchanger includes the first die plate and the second die plate, and the filter plate set between the first die plate and the second die plate. The plastic is plasticized and compacted in the barrel, and the filter plate flows through the head neck through the head neck into the molding die through the head neck through a certain flow path. In the existing technology, the seal of the net exchanger is realized by a seal between the second die plate and the filter plate. However, the machining precision and the installation of the component itself have a gap between the seal and the second die plate and the filter plate, which can not be fully sealed. When the molten material flows through the screen changer, it will be from two blocks. Overflow between boards requires manual cleaning and treatment. By adding a number of detachable seal blocks between the mold and the filter plate, the sealing ring can effectively solve the problem of material leakage in the screen changer.