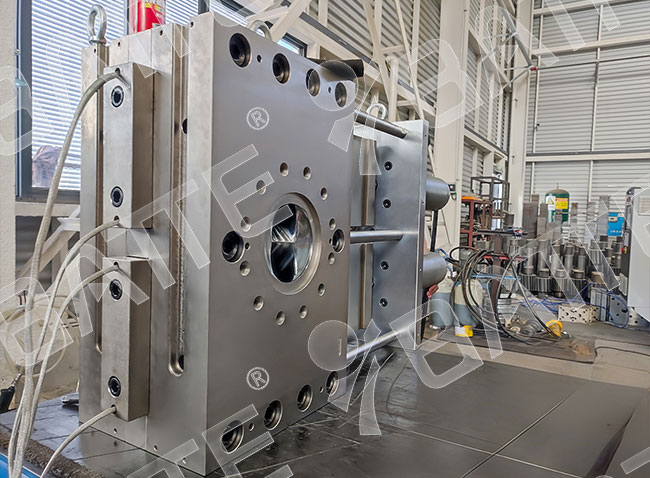

Dual-Plate Non-Stop Screen Changer

The core advantages of the dual-plate non-stop screen changer are primarily reflected in the following aspects:

1. Features a dual-plate, dual-station design where one screen operates while the other is replaced, enabling screen changes without production downtime and boosting efficiency by over 20%.

2. The dual-filter structure doubles the filtration area, effectively removing impurities and ensuring melt quality.

3. User-friendly operation: Screen changes are performed via hydraulic systems or intelligent controls, reducing manual intervention.

4. The hydraulic drive system enables faster screen changes with minimal pressure fluctuations, minimizing production interruption risks.

5. Application scenarios: Suitable for plastic processing and recycling sectors, as well as high-end manufacturing applications such as pelletizing, film blowing, and pipe production.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071