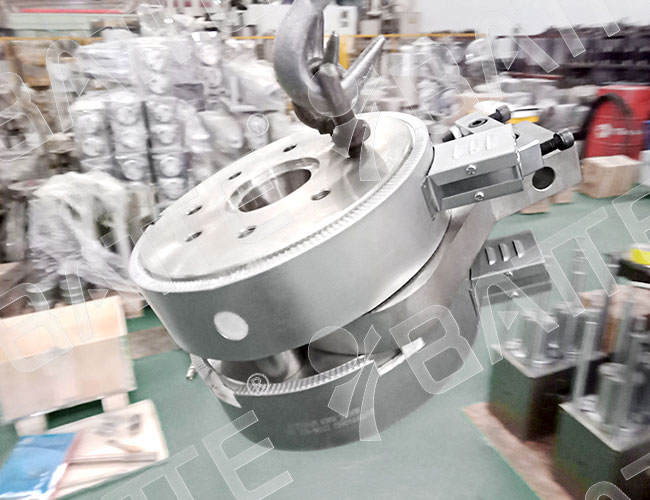

manual screen changer for lab extruder

The manual screen changer for laboratory extruders is a critical auxiliary component installed between the discharge port of laboratory-grade extruders and the die head. Its primary function is to filter impurities, gel particles, and other foreign matter from the melt, ensuring the purity of extruded materials and the quality of subsequent products (such as films, filaments, and profiles). It also protects the precision flow channels of downstream die heads. This equipment is widely used in laboratory R&D and small-batch testing scenarios for plastics, rubber, composite materials, and similar applications.

Advantages

Simple Structure: Low manufacturing cost, compact size, suitable for limited laboratory installation space.

User-Friendly Operation: Requires no complex electrical or hydraulic systems; manual screen changes enable low maintenance barriers.

Cost-Effective: Eliminates additional power consumption; low-cost consumables like screens and seals suit budget-conscious lab environments.

Flexible Adaptability: Quickly interchange screens of varying precision to accommodate diverse experimental formulations and R&D requirements.

Disadvantages

Requires shutdown/reduced output during screen changes: Manual operation necessitates pausing or decreasing extruder output, leading to material waste and disrupting test continuity—particularly unsuitable for continuous testing requiring high production stability.

High Labor Intensity: Frequent manual operations are required when material impurity levels are high or screen changes occur often, increasing workload.

Significant Pressure Fluctuations: Switching melt flow paths during screen changes causes instantaneous pressure fluctuations, potentially affecting product dimensional accuracy or surface quality.

Application Scenarios

Primarily used for laboratory R&D, formulation optimization, and small-batch sample production in plastics, rubber, and composite materials, such as:

Filtration of agglomerated fillers in plastic modification tests (e.g., filler modification, reinforcement modification);

Laboratory testing for recycled plastic materials, filtering impurities from recycled feedstock;

Extrusion molding tests for specialty resins (e.g., high-temperature resins, biodegradable resins);

Formulation development for rubber products, filtering vulcanization impurities and mechanical contaminants from rubber.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071