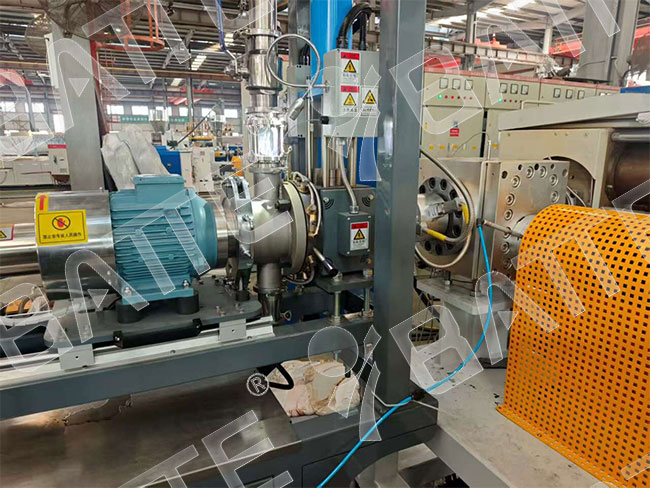

Plastic granulation extrusion continuous screen changer

The dual-column screen changer for plastic pelletizing is a critical piece of equipment in plastic extrusion production lines, enabling continuous filtration of impurities. Its dual-column, dual-station or quad-station design allows for non-stop screen changes, ensuring production continuity and product quality. It is suitable for high-capacity, high-quality plastic processing applications.

Core Features

Non-Stop Screen Change: The dual-column changer employs a dual-column dual-station or quad-station design. During normal operation, multiple screens work simultaneously. When changing screens, one screen remains active while the other is replaced, enabling non-stop screen change without interrupting material flow or product output, ensuring continuous production.

High-Efficiency Filtration: Incorporates material charging and venting systems to thoroughly expel trapped gases from both the feedstock and the porous plate being replaced. This prevents gas inclusion in the product during screen changes, enhancing product quality. Additionally, the dual- or quad-channel design increases filtration area, meeting demands for higher quality and output.

Superior Sealing: Utilizes pressure-driven rigid sealing technology to prevent leakage and extend service life. Sealing gaps automatically compensate during operation, ensuring zero material leakage under high-temperature, high-pressure conditions. This effectively reduces screen-changing resistance and lowers hydraulic system operating pressure.

Wide Applicability: Supports high-volume extrusion of any polymer and integrates with extruders of various standards. Suitable for diverse materials and products including pellets, pipes, sheets, synthetic fibers, cast films, and more.

II. Working Principle

The dual-column screen changer achieves continuous production through alternating operation of two parallel filter columns. During normal production, multiple screens operate simultaneously, filtering material as it passes through. When screen replacement is required, the hydraulic system controls the operational state, allowing one screen to continue working while the other undergoes replacement. During the changeover process, the material feeding and venting systems thoroughly expel trapped gases from both the material and the porous plate being replaced, ensuring continuous product flow and stable quality throughout the screen change.

Application Areas

The dual-column screen changer is widely used in the plastic processing industry, including but not limited to the following applications:

Direct Extrusion: Such as films, profiles, sheets, pipes, fibers, strapping bands, and pelletizing of extruded strands.

Blending: Such as underwater pelletizing, water ring pelletizing, and strand pelletizing.

Raw Material Production: Such as polymerization production lines.

Recycling Production: Such as recycled material production, production of scrap from manufacturing processes, and production of production offcuts.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071