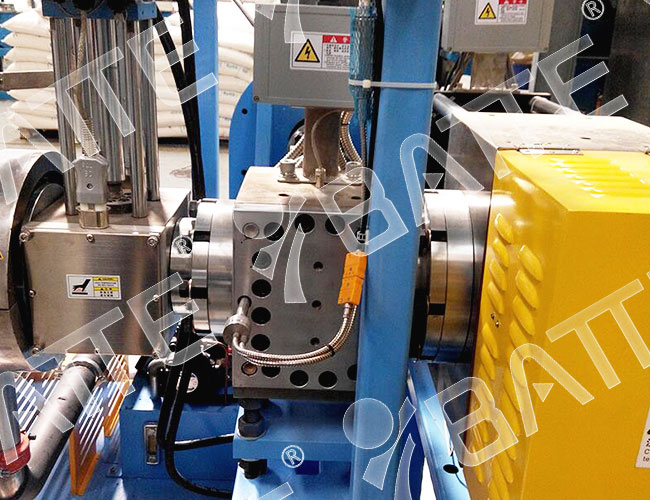

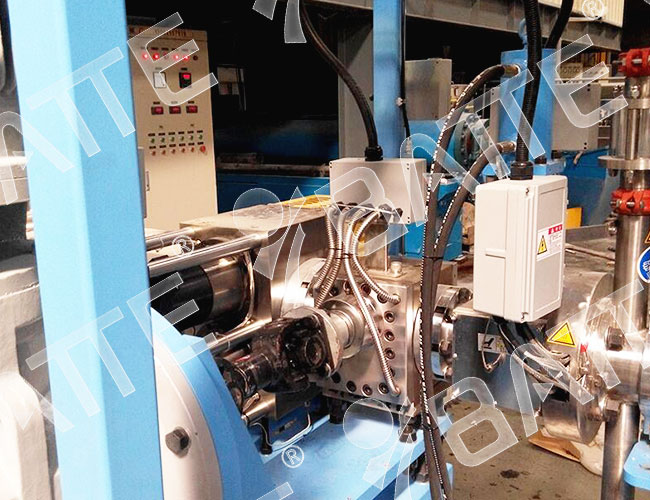

Twin-Column Hydraulic Screen Changer for Plastic Pelletizing Production Lines

The plastic pelletizing screen changer is installed between the extruder and the die head to filter melt impurities, ensuring continuous production and product quality. Its core function is to intercept impurities, unplasticized particles, and decomposition residues in the melt through the filter screen, preventing contaminants from entering the die head and causing flow channel blockages or product defects. The dual-column hydraulic screen changer offers significant advantages in plastic pelletizing extrusion lines. Featuring a dual-column, dual-station design, high-efficiency filtration, non-stop screen changes, and stable sealing, it serves as critical equipment for ensuring production continuity, enhancing product quality, and reducing energy consumption.

I. Specific Applications in Plastic Pelletizing Production Lines

High-Efficiency Filtration and Continuous Production

Expanded filtration area: The dual-station design doubles the filtration surface, effectively intercepting melt impurities (such as unplasticized particles and decomposition residues) to enhance product purity.

Non-Stop Screen Changes: Material flow remains uninterrupted during screen changes, preventing defects like strand breaks and black spots caused by downtime. This is particularly suitable for applications demanding high continuity, such as strand pelletizing and cast film production.

Minimal Pressure Fluctuations: Screen changes cause lower material pressure fluctuations than traditional equipment, ensuring stable product dimensions and surface quality.

Adaptation to Complex Materials

Recycled Material Processing: In plastic recycling pelletizing, the dual-column hydraulic screen changer efficiently filters impurities (e.g., metal fragments, paper debris) from recycled materials, reducing mold wear and scrap rates.

High-Filler Applications: When processing materials containing fillers (e.g., calcium carbonate, glass fiber), its rigid sealing structure withstands high shear forces, preventing material leakage and equipment damage.

Energy Savings and Consumption Reduction

Waste Reduction: Non-stop screen changes minimize production downtime waste, boosting material utilization by 5%-10%.

Energy Efficiency: Stable pressure conditions reduce extruder motor load, lowering overall energy consumption by 8%-15%.

Technical Advantages and Performance Features

Superior Sealing Performance

Rigid Sealing Design: Utilizes high-strength alloy steel sealing components with hydraulically controlled clamping force to ensure precise sealing surface contact. Withstands high temperatures and pressures (typically exceeding 30MPa) to eliminate melt leakage.

Extended Lifespan: Seals undergo specialized heat treatment, delivering superior wear resistance compared to traditional flexible seals and extending maintenance intervals by 2-3 times.

Optimized Flow Path

Streamlined Internal Structure: Melt channels eliminate right-angle dead zones, reducing degradation or carbonization caused by material stagnation and enhancing product purity.

Low Flow Resistance: Smooth channel design minimizes melt shear force, reduces energy consumption, and facilitates cleaning and maintenance.

Ventilation and Feed System

Progressive Venting: During screen changes, the feed vent position pauses to expel air from the plunger via a small material flow, preventing air bubbles from contaminating the product and improving surface quality.

New Screen Preheating: The venting process simultaneously preheats the new screen, minimizing production disruptions caused by temperature fluctuations.

Selection and Configuration Recommendations

Based on Raw Material Characteristics

Highly Contaminated Materials: For recycled materials or those containing fillers, select models with large filtration area (e.g., screen diameter ≥ screw diameter) to ensure filtration efficiency.

High-Viscosity Materials: Choose models with higher hydraulic drive pressure (e.g., ≥25MPa) to accommodate high-shear environments.

Matching Extruder Parameters

Output Matching: Select a screen changer flow rate range based on extruder output (kg/h) to avoid under-sizing or resource waste.

Screw Type: Standard models suffice for single-screw extruders; twin-screw extruders require models with higher pressure ratings.

Additional Function Configurations

Automatic Control System: Integrate PLC or DCS systems for real-time pressure/temperature monitoring and automated screen changes to enhance automation.

Safety Guard: Prevents high-temperature melt splashes to ensure operator safety.

BATTE Melt Pump Factory offers customizable screen changers in various models. Inquiries are welcome.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071