Blown Film ExtruderScreen Changer

The blown film screen changer serves as the core filtration equipment in blown film production. Its primary function is to filter impurities from the melt through screens, ensuring film quality, while enhancing production continuity through non-stop screen changing technology.

I. Working Principle and Structural Types

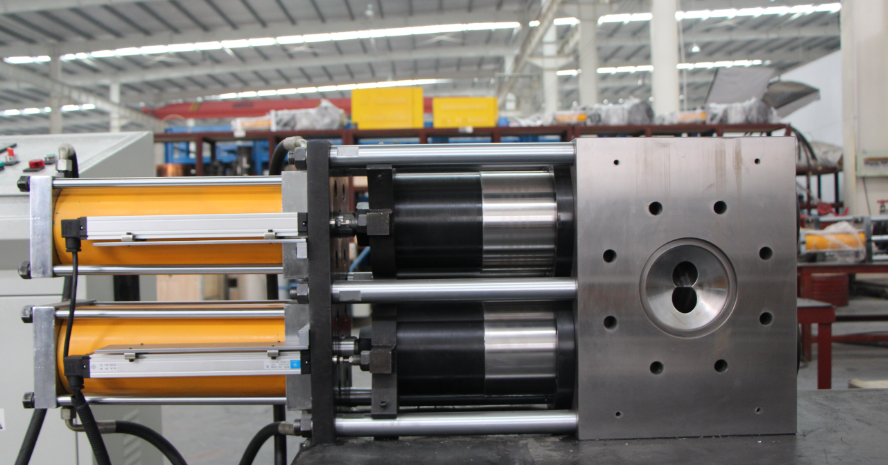

Dual-Column/Dual-Plate Screen Changer

Structure: Features a dual-channel, dual-station design where two screens operate simultaneously (one active, one standby).

Screen Change Process: When impurities accumulate to a threshold on the active screen, a hydraulic or electric system drives the standby screen into position while the original screen retracts for cleaning or replacement.

Advantages:

Non-stop Screen Change: Melt pressure fluctuation during change ≤±1%, maintaining uninterrupted material flow and preventing film breakage.

High-Efficiency Filtration: Over 30% larger filter area than single-screen units, extending single filtration cycles by 30%-50% and reducing change frequency.

High Pressure/Temperature Resistance: Withstands operating pressures ≤35MPa and temperatures ≤400°C, suitable for highly filled (filling rate ≤60%) or high-performance plastics (e.g., PA, PC).

Single-Column Dual-Station Screen Changer

Structure: Features two filtration channels on a single column, with hydraulic cylinders driving alternating screen block switching.

Features:

Compact Design: Suitable for space-constrained production lines, such as small film blowers or multi-layer coextrusion equipment.

Rapid Screen Change: Change time ≤3 seconds, meeting high-speed production demands (e.g., line speed ≥100m/min).

Low-cost maintenance: Independent filter block replacement reduces consumable expenses.

Manual Screen Changer

Structure: Filter switching operated via mechanical handle, eliminating hydraulic or electric systems.

Suitable Applications:

Low-capacity production lines (e.g., daily output ≤5 tons).

Cost-sensitive small enterprises or laboratory equipment.

Limitations: Requires shutdown for screen changes, causing production interruptions and material waste.

II. Application Scenarios and Selection Recommendations

General Film Blowing Production

Recommended Equipment: Dual-column hydraulic screen changer.

Reasoning: Balances performance and cost, compatible with conventional plastics like PE and PP, meeting most packaging film production needs.

Premium Film Production

Recommended Equipment: Fully Automatic Hydraulic Double-Plate Screen Changer.

Reasons:

Filtration precision up to 20μm, meeting optical-grade film production requirements (e.g., BOPET).

Integrated pressure sensors and PLC control system enable automatic pressure compensation during screen changes, ensuring process stability.

Recycled Plastic Film Blowing

Recommended Equipment: Large-Area Double-Plate Screen Changer (filter area ≥0.2m²) .

Reasons:

Efficiently filters impurities (e.g., paper scraps, metal shavings) from recycled materials, enhancing mechanical properties of recycled film (tensile strength increases by 10%-15%).

Wear-resistant design (e.g., carbide filter frame) adapts to extrusion conditions involving highly filled recycled materials (filler content ≥40%).

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071