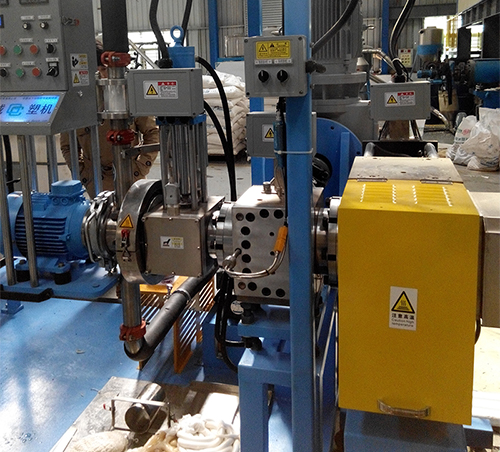

screen changer for plastic pelletizing production line

A screen changer is a manual or automatic switching device comprising one or more screens for filtering out foreign particles and impurities as the plasticized material flows through the screens. The screens are supported by an alloy perforated plate mounted on a plate or column carrier which can be moved to switch between a working position in the system and an off-line non-working position. The screen changer can be installed on any new or existing extruder, melt pump, reactor or other extrusion line. It can be used to filter any type of polymer, rubber or ceramic melt.

Functions:

Filtering Impurities: The primary function of the screen changer is to filter impurities from the melt, ensuring the purity of the melt and thereby improving the quality and performance of the products.

Enhancing Production Efficiency: By enabling quick screen replacement, the screen changer reduces downtime caused by screen blockages, improving the continuous operation capability of the production line.

Types:

There are various types of screen changers, such as manual screen changers, hydraulic quick screen changers, and non-stop screen changers. Among them, non-stop screen changers can replace screens without interrupting production, greatly enhancing production efficiency.

Applications:

The screen changer is also widely used in plastic pelletizing production lines, especially in scenarios where product quality requirements are high. By selecting the appropriate type of screen changer and screen specifications, the needs of different production lines can be met.

Melt filter screen changers for applications in extrusion lines for plastics, rubber, chemical fibers and ceramics. These screen changers - ranging from low-cost manual screen changers to highly sophisticated automatic screen changers with non-stop pressure stabilization - are available for extruders with screw diameters from 35 mm to 300 mm.

Screen changers are commonly used in the following lines:

1. extrusion pelletizing lines from plastic resin synthesis reaction units to bulk pellets.

2. ceramic extrusion lines.

3. polymer (plastic and rubber) molding lines, including blown film, cast film, sheet, pipe, profile, plastic recycling, pelletizing, drawing, underwater pelletizing, masterbatch pelletizing, and extrusion laminating lines.

4. Suitable for all kinds of granulators, extruders, blown film machines, wire drawing machines, sheet extruders, pipe extruders.

Apply different types of screen changers to meet different applications and process requirements. Manual type or low speed screen changer requires that the line must have a short period of time to stop filtering in order to make the change, while high speed screen changer and some special structure screen changer can realize the screen change without stopping or change the screen when slowing down the extruding speed.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071