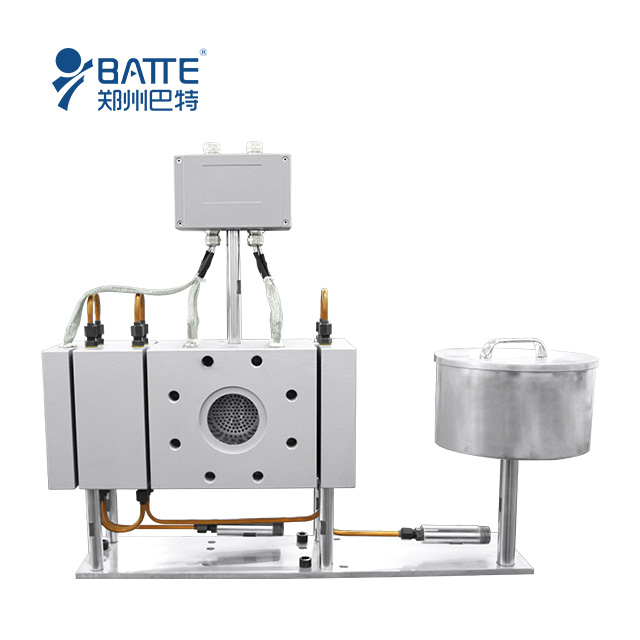

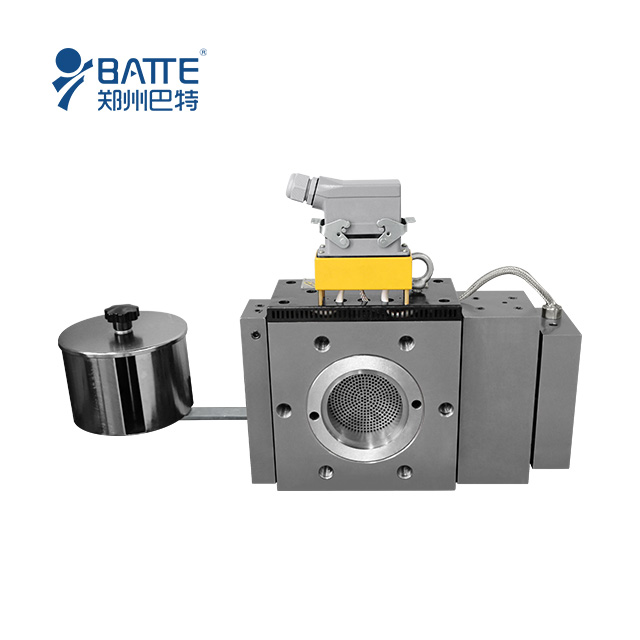

Advantages of fully automatic screen changer for extruders

Fully automatic screen changer has multiple advantages such as high efficiency automation, stable material flow, energy saving and environmental protection, easy maintenance and so on. Specific features are as follows: it can realize automatic continuous screen replacement without manual intervention, which greatly reduces the labor intensity of workers and improves the production efficiency.

At the same time, the automatic screen changer ensures the stability of product quality with no fluctuation of material flow during the screen changing process. In addition, the length of the screen can be customized as required, which is suitable for long time continuous production. It adopts water-cooled sealing method, which reduces the waste of raw materials, lowers the energy consumption, and also reduces the pollution to the environment.

The fully automatic screen changer also has an intelligent control system that can automatically start and stop screen changing according to the set pressure or time parameters, realizing precise control. Its structure is reasonably designed and usually adopts modularized design, which is easy to disassemble, repair, clean and maintain.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071