How can the hydraulic screen changer be changed without stopping?

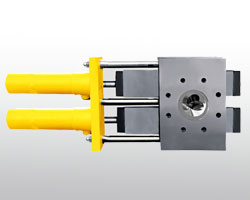

At present, the mesh screen changer can be divided into manual mesh screen changer, electric mesh changer, pneumatic mesh changer, hydraulic mesh changer and so on according to the power of mesh changer, among which hydraulic mesh changer is the most widely used.

For manual mesh screen changer, electric mesh changer, pneumatic mesh screen changer; according to the power of the mesh changer, the meaning is to use manual mesh changer, motor-driven mesh changer, pneumatic mesh changer, because the pressure of the melt in plastic production in a few to 50 Mpa, so in actual production these kinetic energy can not be achieved under the working condition to replace the mesh. Therefore, it is necessary to shut down the engine or reduce the pressure drop of the extruder. As for the hydraulic mesh screen changer, the maximum kinetic energy pressure of 20Mpa can be achieved by using the hydraulic pump station to provide power, so as long as the melt pressure does not exceed 50Mpa, it can realize the non-stop mesh screen changer.