What industries can single-column screen changers be used in?

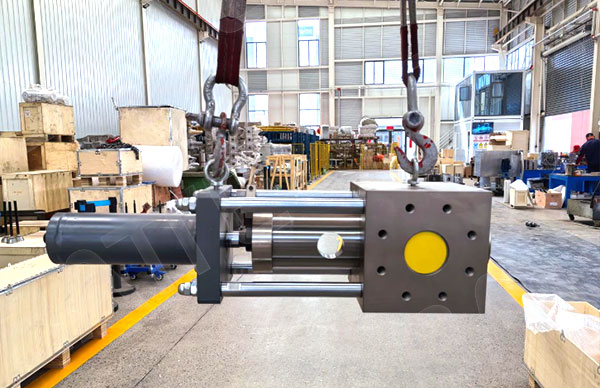

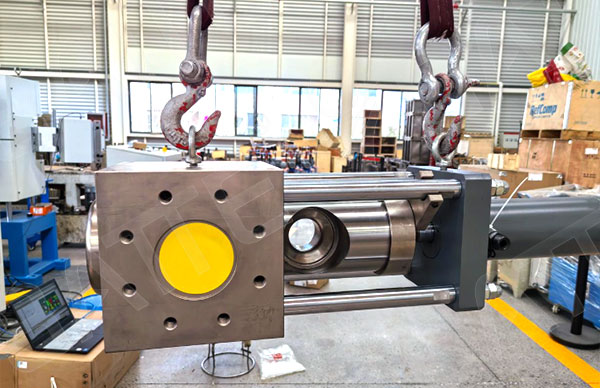

Don't let its compact size fool you—this little single-column screen changer is a quiet powerhouse in industrial production! While many may not be familiar with it, it's quietly solved major headaches for numerous industries. Today, let's explore its key applications and why these sectors can't do without it.

First, let's address the pain points:

Have you ever encountered these situations?

Impurities constantly clogging the die during plastic extrusion, forcing shutdowns for cleaning and delaying production schedules

Frequent fiber breaks during chemical fiber spinning, leading to persistently high defect rates

Crystal spots or holes appearing in blown film, making the finished product look “patched up”

These issues often stem from inadequate melt filtration—and the single-column screen changer is specifically designed to tackle this “problem”!

Key Application Industries:

Plastics Manufacturing

Film blowing/cast film production: For ultra-thin products like supermarket bags and cling wrap, the screen changer filters carbonized particles from the melt, ensuring a silk-smooth film surface

Pipe/sheet extrusion: Continuous 72-hour operation without screen changes is standard practice for manufacturing PVC water pipes and PPR pipes

Injection Molding: For products demanding high surface finish like automotive plastic parts and appliance housings, screen changers are indispensable—like removing a beauty filter from a smartphone.

Chemical Fiber & Textile Industry

Polyester/Nylon Spinning: Equivalent to installing a “water purifier” for the melt, eliminating “hair-like” breaks caused by spinneret blockages.

Nonwoven Fabric Production: Medical-grade spunbonded fabrics demand zero defects—screen changers serve as the quality gatekeepers.

Especially suited for producing ultra-fine filaments (20 times thinner than hair!), making production impossible without it.

Specialty Materials Sector

Biodegradable materials: Temperature-sensitive “delicate” materials like PLA/PBAT benefit from the gentler single-column structure of screen changers

Cable compound production: Conductive fillers like copper powder prone to agglomeration? Multi-layer filter screens to the rescue!

Masterbatch pelletizing: Uneven pigment dispersion? Screen changers act as a “stirring rod” for flow

Hidden Skills Unlocked:

Food packaging industry: FDA-certified screen changers even filter materials for yogurt lids

Recycled material processing: Tackles sand-laden or metal-contaminated waste plastics as a “melt purifier”

Lab applications: Miniature screen changers pair seamlessly with research-grade micro-extruders

Next time you see sleek beverage bottles, sturdy woven bags, or blue non-woven surgical gowns in operating rooms, this little device might be quietly powering it all! Different industries prioritize different needs—choosing the right model is like picking glasses: the perfect fit is key

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071