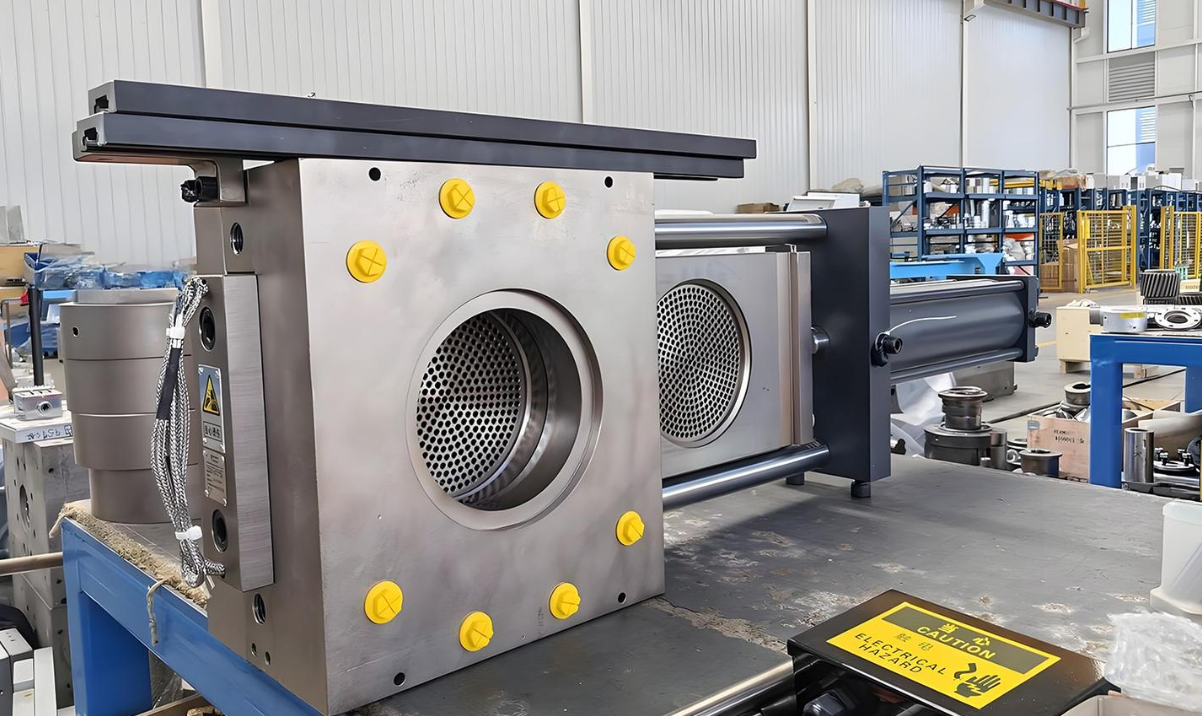

Single-Plate Hydraulic Screen Changer for Sheet Drip Tape

In sheet drip tape production lines, the single-plate screen changer serves as the critical filtration equipment. It filters impurities, scorch, and other foreign matter from molten plastic, preventing blockages in mold channels or contamination of the drip tape. This ensures uniform wall thickness and unobstructed emitters, thereby enhancing product quality. Key advantages include:

Rapid Screen Change: The single-plate screen changer in drip tape production lines can switch filters within 1 second. This swift operation minimizes material flow disruption and prevents leakage. This rapid change design significantly reduces production downtime caused by screen changes, boosting efficiency.

High Pressure Resistance: The changer exhibits exceptional pressure tolerance, with a peak rating of 50 MPa, meeting demands in high-pressure production environments.

Large Filtration Area: Featuring an expansive filtration surface, the changer effectively removes impurities and particles from the fluid. This ensures high material purity entering the drip tape production mold, thereby guaranteeing the quality and performance of the final product.

Short, Straight Flow Path: The screen changer's flow path is designed to be short and straight with no dead corners. This minimizes material residence time in the flow path, reducing the likelihood of material degradation while also boosting production efficiency.

Uniform Heating: The screen changer employs internal heating, offering rapid heating with uniform temperature distribution and low energy consumption. This heating method helps maintain stable melt temperature, enhancing production quality.

Simple operation: The screen changer is relatively easy to operate. When impurities accumulate to a certain level on the filter screen during operation, simply press the control handle button on the hydraulic station to activate the accumulator-driven hydraulic system for screen changing. This design allows operators to complete screen changes effortlessly, reducing operational complexity.

Minimal Screen Change Waste: Featuring a dual-station design and rapid screen change action, the device generates minimal waste during screen replacement. This contributes to reduced production costs and improved resource utilization.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071