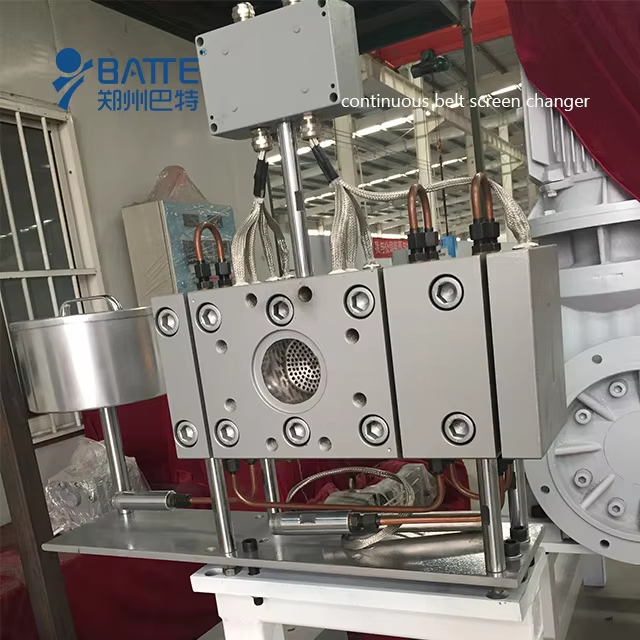

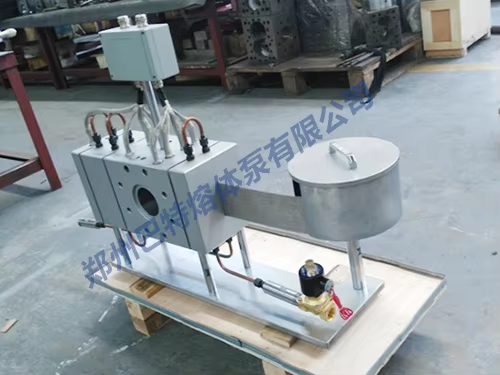

Mesh belt type hydraulic screen changer

The mesh belt-type fully automatic screen changer is a critical piece of equipment used in plastic extrusion, film production, and other fields to filter impurities from molten materials. Its core feature is the continuous circulation of the mesh belt structure, enabling non-stop automatic screen changes while balancing high-efficiency production with precision filtration requirements.

1. Maintains stable material flow pressure during screen changes, preventing film thickness variations or optical distortions caused by pressure fluctuations. This is particularly suitable for high-transparency products like flow-milling, blown film, and chemical fiber spinning.

2. Fully automated operation requires no manual intervention. The filter continuously removes melt impurities, significantly boosting production efficiency and minimizing downtime. Compared to manual changers, it achieves several times higher change efficiency, meeting the demands of extended continuous production runs.

3. Integrated pressure sensors and control systems automatically trigger screen changes based on real-time pressure readings, eliminating manual intervention and reducing operator workload.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071