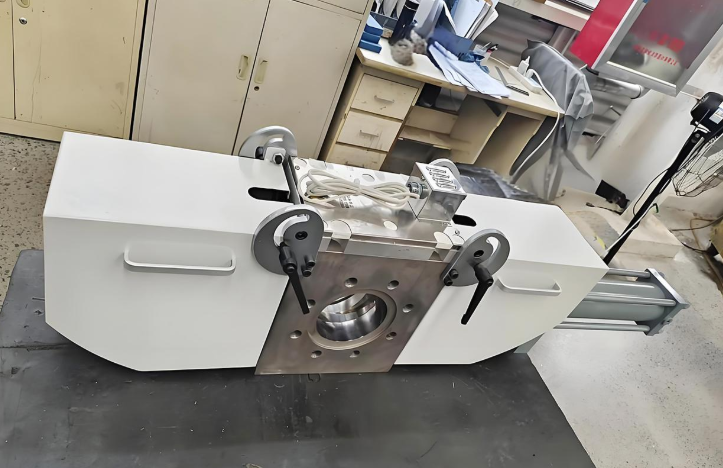

polymer melt filter screen changer

What is a Screen Changer? A Must-Know for Plastic Processors!

Simply put, a screen changer is the “cleaning expert” of plastic extrusion production lines. It's primarily installed between the extruder and the die, filtering impurities and carbonized particles from the melt to ensure material purity. After all, plastic raw materials may contain dust or metal shavings, and processing can generate carbon particles. If these enter the mold, they can cause product defects or even damage equipment.

Common types include manual and hydraulic models. Dual-column hydraulic screen changers even allow for non-stop screen changes without halting production.

In short, if you want flawless extruded products and minimal equipment wear, the screen changer is a crucial player!

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071