Plastic Extruder Screen Changer Application Areas

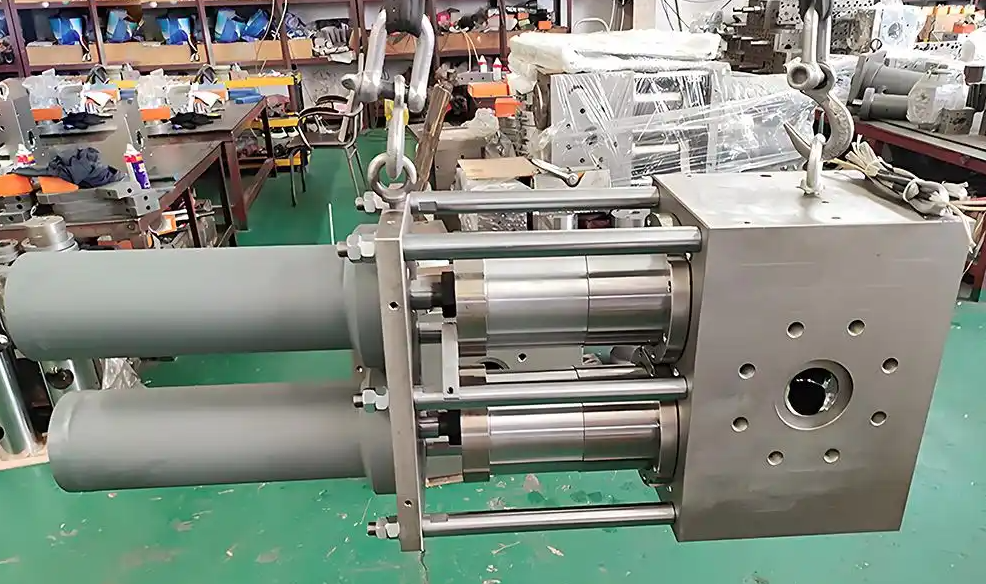

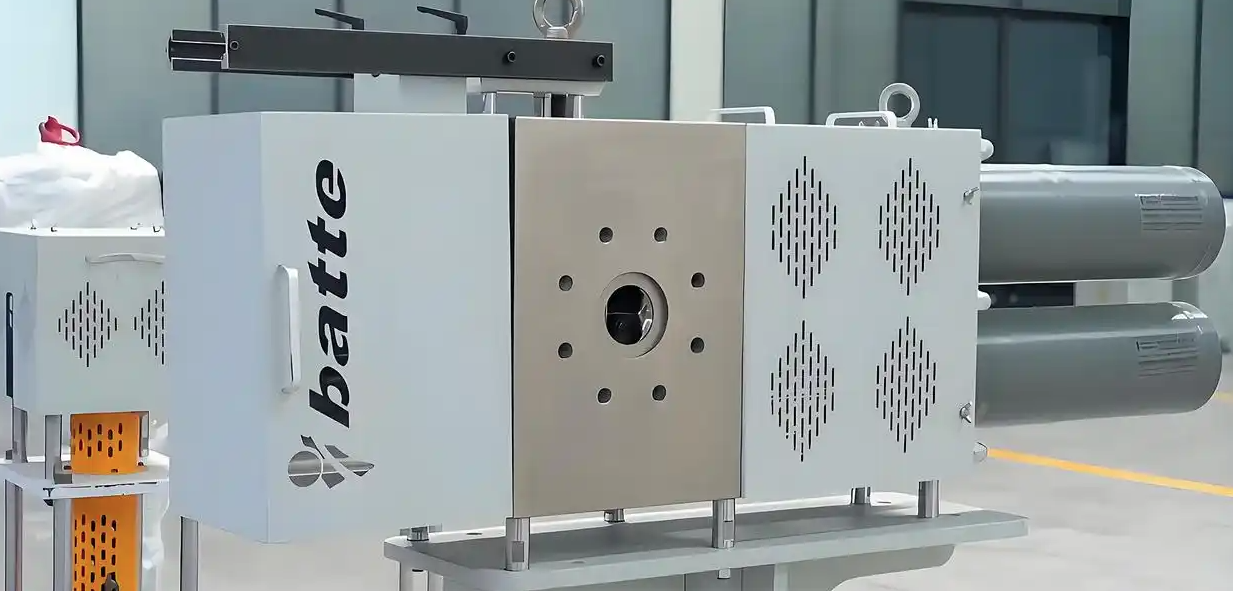

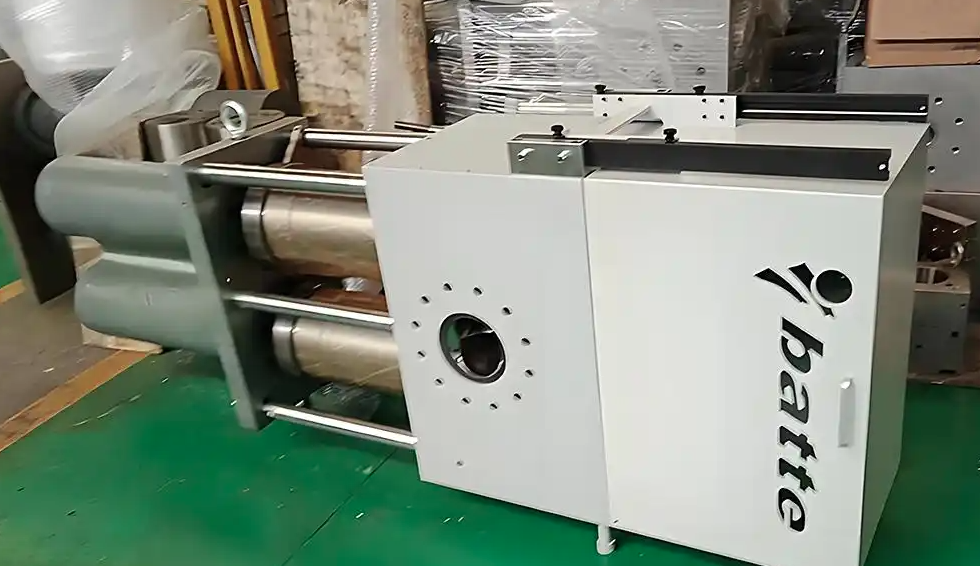

Plastic extruder screen changer is the key filtration part connecting the extruder and die head, mainly used to intercept the impurities, coke and unplasticized particles in the plastic melt, and at the same time, realize the non-stop screen changer in order to guarantee the continuity of the production, which is widely used in the plastics extrusion processing and the core of the function.

Main application fields

Plastic pelletizing field: covering PE, PP, PVC, ABS and other general-purpose plastics and PA, PC and other engineering plastics pelletizing, especially suitable for recycled material pelletizing (high content of impurities) and modified plastics pelletizing (need to filter filler agglomerated particles), to ensure the cleanliness and homogeneity of particles.

Profile / pipe extrusion: such as PVC door and window profiles, PPR water supply pipe, HDPE gas pipe extrusion, filtering impurities to avoid surface scratches on the profile, pipe wall bumps and other defects, to protect the product dimensional accuracy and mechanical properties.

Film / sheet extrusion: including BOPP film, PET sheet, PVC flexible film production, effective interception of impurities to prevent film holes, sheet pockmarks, to maintain the optical properties of the product and surface finish.

Cable extrusion: in the cable insulation layer, sheath material extrusion, filtering impurities can avoid cable surface bulging, insulation layer breakdown and other problems, to protect the electrical insulation properties of cables.

Composite extrusion field: such as multi-layer co-extruded film, functional masterbatch composite extrusion, to ensure the cleanliness of each layer of the melt, to avoid delamination or composite defects.

Core Functions

Impurity filtration: intercept mechanical impurities (e.g. metal chips, sediment), process impurities (e.g. coke, unplasticized particles) and foreign matter in recycled materials through metal filtering mesh in the melt to enhance the purity of the melt and reduce product defects from the source.

Non-stop screen change: Hydraulic drive is adopted to realize non-stop screen change, avoiding the waste of raw materials, production interruption and restarting time cost caused by screen change, and greatly improving production efficiency.

Suitable for a variety of working conditions: according to the melt viscosity, temperature (suitable for 100-400 ℃), pressure (suitable for ≤ 30MPa) and raw material type, different structures (such as plate, column, duplex) and screen specifications (20-400 mesh) can be used to meet the diversified extrusion needs.

The application scope of plastic extrusion screen changer has been expanded from traditional pipe and film to high-end optical materials, carbon fiber and recycled materials. When selecting the type, it is necessary to take into account the material characteristics, production scale, automation requirements, and intelligent, green is the core direction of the future technological upgrading.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071