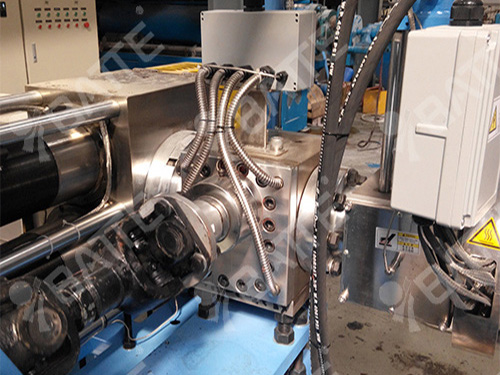

PU TPU granulation extrusion screen changer

Core Functions and Applicability

PU (polyurethane) and TPU (thermoplastic polyurethane) pelletizing processes demand screen changers with specific requirements: temperature resistance, corrosion resistance, and filtration precision:

Temperature Resistance

TPU processing temperatures typically range from 180-220°C, necessitating screen changers with temperature resistance ≥250°C. For instance, dual-column hydraulic screen changers made from alloy steel withstand temperatures up to 300°C, meeting TPU production requirements.

Corrosion Resistance

TPU melt is sensitive to metal ions. Corrosion-resistant alloy steel (e.g., H13 steel) or porous plate coating treatments must be selected to prevent impurity contamination.

Filter Precision

Based on TPU particle requirements, mesh sizes typically range from 80 to 200 mesh. Dual-station screen changers support rapid switching between different precision filters, accommodating multi-specification production.

Hydraulic automatic screen changers (e.g., Zhengzhou Bate dual-column hydraulic screen changers) feature a dual-station design enabling simultaneous operation and replacement of screens. This ensures continuous filtration of TPU melt, preventing material property degradation caused by downtime.

Key Structural & Performance Parameters

Sealing Structure

Features rigid sealing combined with progressive material feed design (e.g., Shandong Najin hydraulic changer) to minimize pressure fluctuations during changes (≤3MPa), preventing TPU melt leakage or degradation.

Flow Path Optimization

Dead-zone-free flow path design eliminates melt stagnation, reducing defects like black spots and bubbles in TPU pellets.

Pressure Resistance

TPU pelletizing die heads typically operate at 15-25MPa; select a screen changer rated for ≥30MPa pressure resistance.

Selection Recommendations

Production Capacity Requirements

Small-scale production (≤500kg/h): Single-plate hydraulic screen changer. Large-scale continuous production (≥1t/h): Double-column hydraulic screen changer.

Budget vs. Efficiency Balance

Hydraulic screen changers involve higher initial investment but reduce scrap rates (from 5% to 0.5%), resulting in lower long-term operating costs.

Brands & Case Studies

Zhengzhou Batte: Specializes in hydraulic screen changers for masterbatch pelletizing, supporting high-filler TPU formulations.

For PU/TPU plastic pelletizing, prioritize hydraulic automatic screen changers with emphasis on temperature resistance (≥250°C), pressure tolerance (≥30MPa), and sealing design. Where budget permits, dual-column hydraulic screen changers maximize production efficiency and product quality.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071