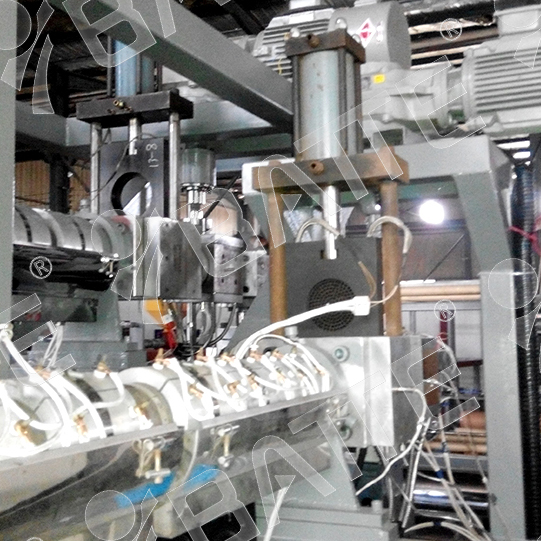

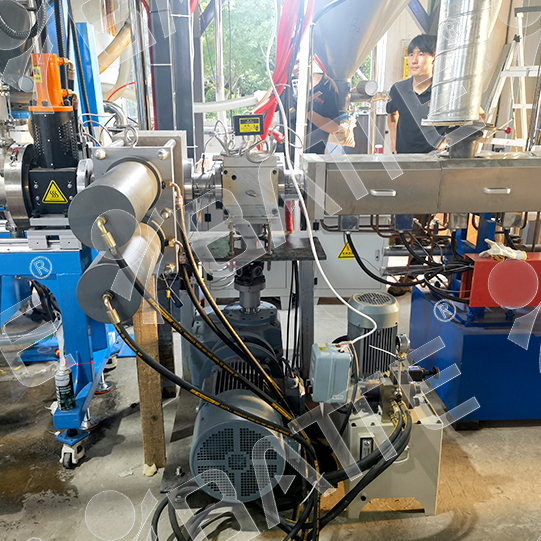

PS Transparent Sheet Extrusion Screen Changer

PS (polystyrene) transparent sheets require a high degree of purity in the melt during the extrusion production process to prevent impurities from affecting transparency and surface quality. The extrusion screen changer, as a critical piece of equipment for filtering impurities from the melt, can effectively improve the production quality of PS transparent sheets. Its selection and application must be tailored to process requirements and equipment characteristics, as detailed below:

1. The Role and Core Functions of Extrusion Screen Changers

Filtering Impurities

Screen changers use filters supported by alloy perforated plates to intercept impurities such as metal shavings, carbides, and unmelted particles in the melt, ensuring the purity of the melt entering the die head. For PS transparent sheets, impurities can cause light scattering or surface defects, and screen changers can significantly reduce scrap rates.

Protecting Equipment

Impurities accelerate wear on components such as molds and screws. The screen changer extends equipment lifespan through filtration, reducing downtime and maintenance costs.

Enhancing Production Efficiency

Automatic screen changers (e.g., hydraulic or belt-type) can replace filters without stopping production, avoiding production interruptions and material pressure fluctuations caused by traditional manual screen changes, ensuring the continuity of PS transparent sheet production.

II. Key Considerations for Selecting PS Transparent Sheet Extrusion Screen Changers

Filter Precision

Select an appropriate mesh size (e.g., 20–300 microns) based on the quality requirements of PS transparent sheets, balancing filtration effectiveness with melt flowability.

High-precision screens (e.g., 300 mesh or higher) are suitable for products with extremely high transparency requirements, but pressure drop control must be managed carefully.

Screen Change Method

Manual screen changers: Low cost but require shutdown for operation, suitable for small-scale or low-value-added production.

Hydraulic automatic screen changers: Rapid screen change (0.5–10 seconds) with strong sealing performance, suitable for continuous production of PS translucent sheets.

Belt-type fully automatic screen changers: Utilize pressure-driven belt circulation filtration with no waste generation, particularly suitable for processing recycled PS material with high impurity content.

Temperature and Pressure Resistance

PS melt temperature typically ranges from 180–240°C, so a screen changer with temperature resistance exceeding 300°C must be selected (e.g., using 316L stainless steel or cobalt-based alloy-coated filters).

Pressure loss must be controlled below 5 MPa to avoid affecting extrusion stability.

Structural Compatibility

Select single-plate dual-station, dual-column, or rotary screen changers based on the extruder model (screw diameter 35-300 mm).

For example, single-plate dual-station screen changers are compact with short flow paths, suitable for PS sheet extrusion; rotary multi-disk systems can accommodate 6-8 filter sets, suitable for high-impurity recycled materials.

In PS translucent sheet extrusion production, hydraulic automatic or belt-type fully automatic screen changers are recommended to achieve efficient filtration, continuous production, and equipment protection. When selecting a model, consider filtration precision, temperature and pressure resistance, structural compatibility, and cost-effectiveness, for example:

Small-scale production: manual screen changer (low cost, but requires downtime for screen changes);

Continuous production: Hydraulic automatic dual-column screen changers (balancing efficiency and cost);

Recycled material processing: Rotating multi-disk systems (high durability, suitable for high-impurity scenarios).

Through scientific selection and standardized operation, screen changers can significantly enhance the quality stability and production efficiency of PS translucent sheets.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071