PE foam film extrusion screen changer

Impurity Filtration

PE raw materials may be mixed with impurities such as dust, metal shavings, gel particles, etc. during the production process. The screen changer intercepts these impurities through the screen and prevents them from entering the downstream equipment (e.g., molds, melt pumps), thus reducing defects such as surface imperfections, bubbles, and holes in the products. For example, in the production of XPS foam sheet, the screen changer can reduce the content of impurities to less than 0.01%, which significantly improves the product qualification rate.

Improvement of melt uniformity

The screen changer produces shearing and mixing effects on PE melt during the filtration process, making the temperature, pressure and flow rate more uniform. For example, in the production of PE microcellular foamed film, melt uniformity can be improved to stabilize the foam multiplication rate at 10-30 times, and reduce the range of film density fluctuations to ± 0.05g/cm³.

Equipment Protection and Cost Optimization

Contaminants that get into the screw, barrel or mold can increase wear and shorten equipment life. Screen changers reduce equipment maintenance frequency and downtime. In the case of a PE foam film production line with an annual output of 5,000 tons, for example, the use of a screen changer can extend equipment life by 2-3 years and reduce maintenance costs by about 40%.

Continuous production support

Automatic screen changers (e.g., hydraulically driven type) can change screens without stopping the machine, avoiding production interruptions. For example, in wide-width (≥3m) PE foam film production lines, the automatic screen changer can shorten the screen changing time to 1-3 seconds and reduce the defective rate to less than 0.5%.

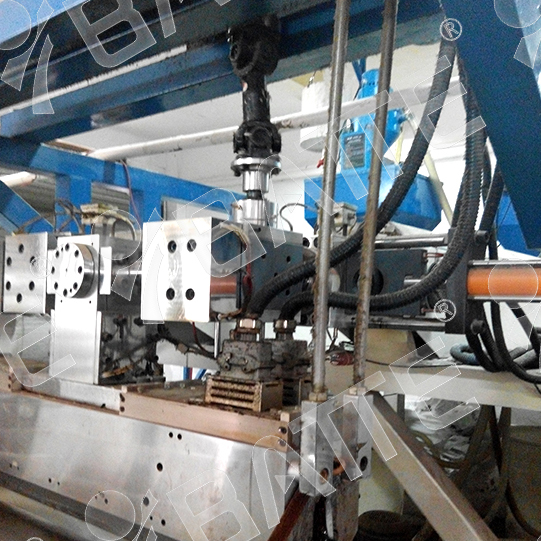

Zhengzhou Batte Hydraulic Plate Screen Changer

Model: MP-H50CC

Features: fast screen changing time <2 seconds, temperature resistance 300℃, suitable for extruders with diameter 50-150mm.

Applications: PE foam film, wood-plastic composites and other scenes.

PE foam film extrusion screen changer needs to be selected according to the process temperature, pressure, output and automation needs comprehensively. Hydraulic automatic or mesh belt type automatic screen changer can significantly improve the production continuity and product stability, while the combination of multi-layer screen and high temperature-resistant material is the key to ensure long-term operation. When selecting the actual type, it is recommended to match the extruder model (e.g. screw diameter ≥ screen diameter) and raw material characteristics (e.g. impurity content of old material) to achieve the best price/performance ratio.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071