Application Scenario of Automatic Non-stop Mesh Belt Screen Changer

As a key equipment in modern plastics processing industry, automatic screen changer plays an important role in the production of high-quality and long-flow products. It is widely used in the production of cast film, film manufacturing, as well as various kinds of wire drawing, granulation and other production processes, and is highly suitable for high-level automated production lines for the stringent requirements of efficient melt filtration.

Advantages of automatic screen changer

has the function of automatic screen walking without stopping, this feature not only greatly reduces the labor intensity of workers and frees operators from the tedious manual screen changing work, more importantly, it significantly improves the production efficiency, effectively reduces the interruption of production due to the stoppage of screen changing, and brings higher output for the enterprise.

During the screen changing process, it ensures that the material flow remains smooth and free from fluctuations. This excellent stability makes the products produced not to appear deformation and other quality problems, strongly guarantee the consistency and stability of product quality, to meet the market demand for high quality products.

The advanced water-cooled sealing method not only effectively reduces the waste of raw materials in the production process, improves the utilization rate of raw materials and reduces the production cost, but also reduces the pollution to the environment, which is in line with the concept of green production and sustainable development.

The screen length is highly flexible and can be customized according to the actual needs of the customer, up to 20 meters. This feature makes it ideal for continuous production over long periods of time, reducing the need for frequent screen changes and further improving production efficiency.

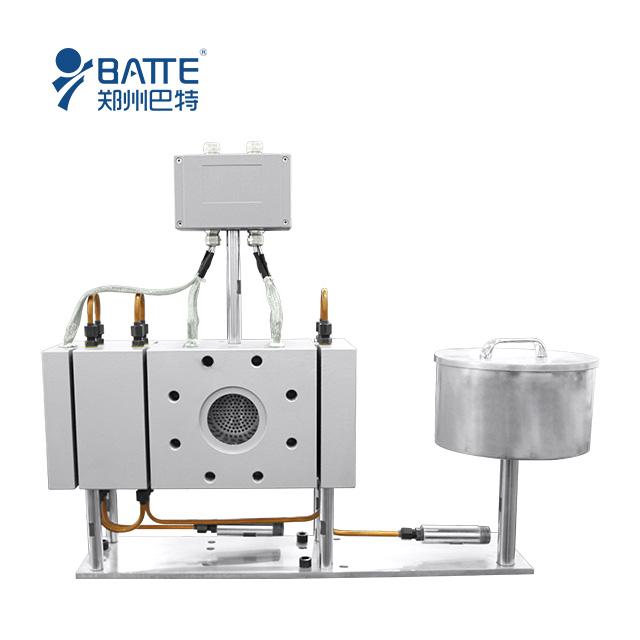

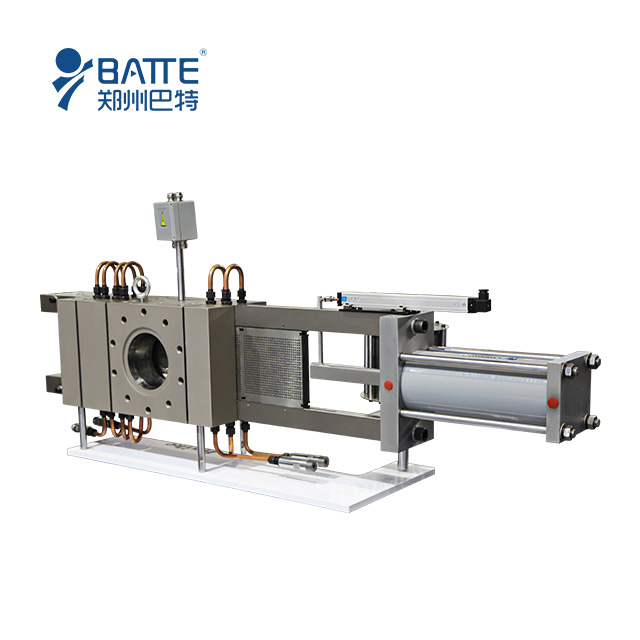

Screen Changer Structure

The Screen Changer consists of a screen belt of either 10 or 20 meters in length, a well-designed screen changer body, an intelligent heating/cooling system, and a precise electronic control system. The entire system is automated and operates efficiently without the need for external intervention. Compared with the traditional manual screen changer, the automatic screen changer with mesh belt has a significant effect on increasing production, saving energy and reducing costs. The screen changer is usually installed in the key position between the extruder and the mold, and its working status is precisely controlled by the advanced electric control system to ensure the stable and efficient operation of the equipment and create greater value for the enterprise.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071