Comprehensive analysis of double-plate double-station non-stop screen changer

Application of working conditions

Double-plate double-station non-stop screen changer is widely used in the extrusion line of sheet, plate, pipe, profile, cast film, pelletizing and other thermoplastic plastics and polymerization line, co-mingling and other materials, and it is the key equipment for realizing high-efficiency and continuous production.

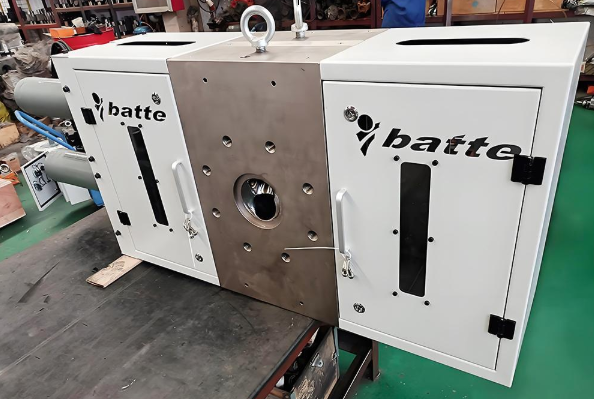

Structural features

Double runner and double station design: double nets work at the same time and change alternately to ensure the continuity and stability of the production process.

Reasonable priming and exhausting structure: small pressure fluctuation in the process of net changing, continuous and stable products.

Split structure design: simple structure, easy maintenance.

Simple operation: easy maintenance, automatic alarm control can be realized to ensure the safe and stable operation of the system.

Technical parameters

Working temperature: ≤350°C

Working pressure: ≤40MPa

Differential pressure: ≤20MPa

Applicable melt viscosity: 100~40000Pa.s

Heating mode: electric heating/heat medium heating

Optional Configurations

Standard configuration: screen changer body + hydraulic pump station + heating device

Customized configuration: screen changer body + hydraulic pump station + heating device + electrical control cabinet

Email: sale@meltpump.com

WhatsApp: +86 158 38331071