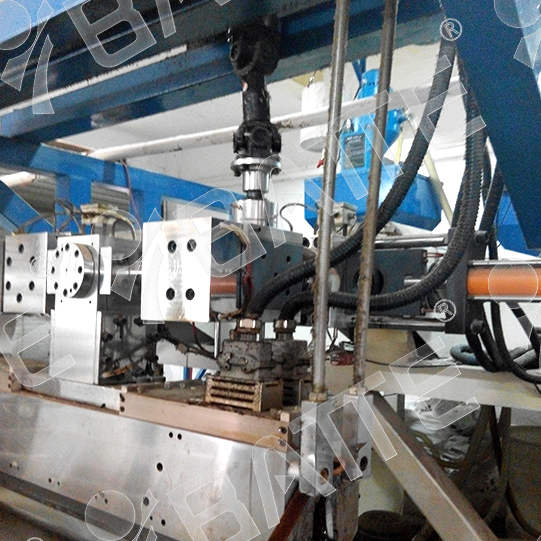

Hydraulic screen changer for sheet extruders

The advantageous features of the hydraulic screen changer for sheet extruder mainly include the following points:

First, without stopping to change the net, improve production efficiency:

Double-column double-station design: the hydraulic screen changer for sheet extruder adopts double-column double-station design, with two screens working at the same time. When it is necessary to change the screen, one screen is in working condition and the other one is replaced, realizing the operation of changing the screen without stopping. This greatly improves the production efficiency and reduces the production interruption and scrap caused by the screen change downtime.

Second, efficient filtration to ensure product quality:

Effective filtration of impurities: It can filter out impurities in the melt, including unplasticized fine plastic particles, foreign matter, etc., ensuring the surface quality and internal properties of the sheet.

Adjustable filtration precision: different mesh filters can be selected according to different production requirements, to meet the demand for impurity filtration precision of various sheet products.

Third, large filtration area, adapting to large-scale production:

Handle large flow of materials: compared with other types of screen changer, double column screen changer usually has a larger filtration area, which can handle larger material flow and is suitable for large-scale sheet production.

Reduce screen clogging: larger filter area reduces the frequency of screen clogging, reducing the number of times to change the screen.

Fourth, the pressure flow is stable to ensure the molding quality:

Small pressure fluctuation: In the process of screen changing, due to the alternating working mode of double columns, the material flow will not be interrupted, and the pressure fluctuation is small, which can keep the pressure and flow of the melt stable. This is very important for the molding quality of the sheet, which can make the thickness, width and other dimensions of the sheet more uniform, avoiding uneven thickness, uneven surface and other problems.

Fifth, good sealing performance to prevent material leakage:

Rigid sealing structure: with a good sealing structure design, in the high temperature, high pressure working conditions, can do not leakage, no seepage. This not only ensures the cleanliness of the production environment, but also effectively reduces the resistance of the screen change, reduces the working pressure of the hydraulic system, and extends the service life of the equipment.

Sixth, strong durability and long service life:

High-quality materials manufacturing: the main structure of the double-column screen changer is usually made of high-quality alloy steel and other materials, and after special treatment processes, such as nitriding treatment, etc., so that it has high strength and hardness, and can withstand high temperature and high pressure of the harsh working environment, the use of the cycle is greatly extended.

Seven, optimize the flow channel structure, reduce the residue:

No dead angle, no stagnant flow: the flow channel structure is optimized, no dead angle, no stagnant flow, to ensure that the melt can pass through the screen changer smoothly, reducing the residue and accumulation of materials in the screen changer, avoiding product quality problems and equipment failures due to the residue of materials.

Eight, optional configuration is rich, adaptable:

A variety of configurations to choose from: some double-column screen changer is designed with a priming exhaust system, which can fully eliminate the gas in the material and prevent the gas from forming bubbles and other defects in the sheet. At the same time, according to customer demand to provide high corrosion-resistant materials, movable installation trolley, automatic control system and other configuration options.

Nine. Enhance production safety:

Safety design: some advanced hydraulic screen changers come with safety shielding design, when the shield is opened, the system automatically cuts off to ensure the safety of operation.

In summary, the sheet extruder hydraulic screen changer plays an important role in sheet extrusion production with its advantageous features such as high efficiency filtration, no downtime screen changer, stable pressure and flow, good sealing performance, easy operation, strong durability, etc., which helps to improve production efficiency and product quality.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071