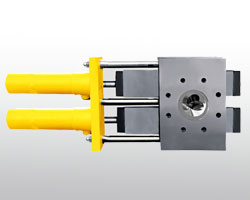

batte Screen changer for extruder

Single plate and double plate, single and double column hydraulic screen changer, quick screen changing, easy operation and maintenance.

With built-in sealing device, the sealing performance is good, which can meet the production of arbitrary polymer high extrusion capacity, and can be used with different standard extruders.

The time for fast changing the network is less than 2 seconds, and the filter area is selected between 30mm- and 250mm.

High abrasion resistance, high pressure resistance and high precision filter screen design, improve effective area and filter quality.

The pressure is 25 - 30Mpa and the temperature is about 300 degrees Celsius.

Almost all polymers can use mesh changers, such as PC, PMMA, PET, PS, PU, PP, PE, EVA, ABS, etc.

Use:

Applicable to high transparency, high viscosity, easy cracking, high molecular weight plastic screen changer filter features: modular leak-proof sleeve, can be self-assembled and disassembled wear steel sleeve, do not need to be further processed. The runner is not stuck with plastic, and the residence time is short. It can be prevented from leakage by adjusting the expansion coefficient of the metal due to the processing temperature. The opening time of the oil pressure starting hole to the hole is about 0.01 seconds, and the production is not interrupted. The steel mold of the filter hole can be separately removed to ensure that the plastic inside the retained hole is cleaned, and the clean steel mold of the filter hole can be quickly replaced to ensure that the plastic behind the filter screen is clean. There is a preheating device that does not slow down the cooling of plastics when changing the net.