How to choose a hydraulic screen changer and what are the supporting auxiliary equipment?

The selection of continuous extrusion hydraulic screen changer should be based on several factors such as material, product type, production volume, material pressure within the system, and automation level. The general principle is: when the product quality is high, the production efficiency is high, the production process is long, and the degree of automation is high, choose a continuous screen changer without stopping the machine. It can replace the filter mesh without interrupting the product, increase production, save energy, operate easily, and have no waste products. The production process is short, the degree of automation is low, and the product quality requirements are not high. You can choose a fast and non-stop screen changer. Quick screen changer saves time, is inexpensive, and saves investment.

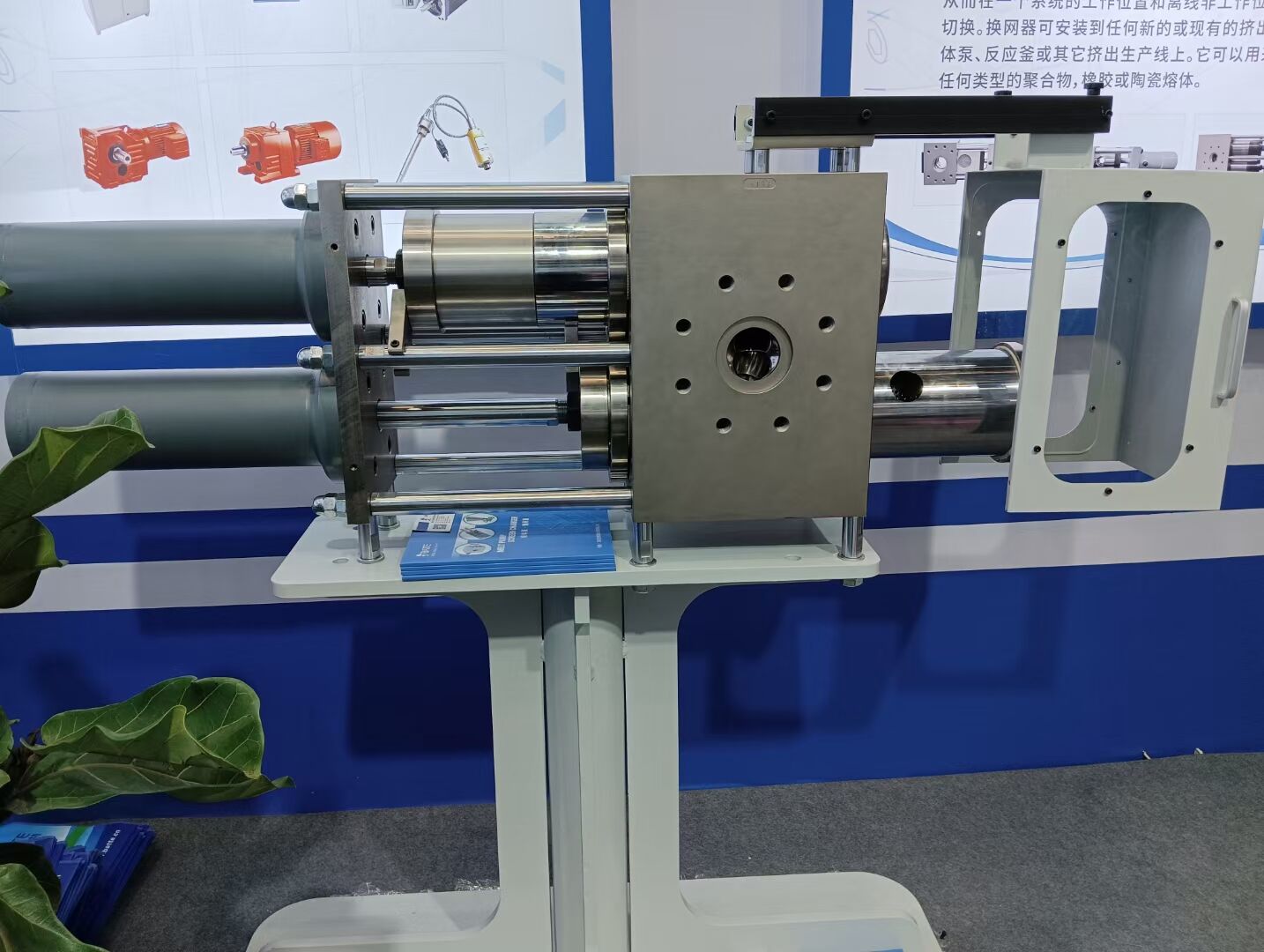

The types of extrusion melt filer hydraulic screen changer include fully automatic, semi-automatic, and manual; The power of the screen changer can be divided into hydraulic, motorized, manual, etc; The main structures of the screen changer include mesh belt type, plate type, cylindrical type, and rotary type. According to needs, automatic temperature control, material pressure measurement and control automatic alarm, and high-pressure sewage discharge system can be selected. The automatic sensing alarm system for material flow and pressure can directly understand the working status of the host and the degree of clogging of the filter screen. It can provide sound and light alarms or automatically change the screen at better changing points, making the screen change more scientific and accurate. The high-pressure sewage automatic discharge system (used for circulation) can reduce the total pressure of the screen changer by 50%, reducing the sliding resistance and wear of the filter block.

The heaters equipped with the plastic extrusion melt filter screen changer include high-energy cast aluminum heating plates and stainless steel heating pipes. When selecting a complete electric control system, users can apply it by powering on. The matched hydraulic pump station valve system is made of high-quality products, with stable and reliable performance; Hydraulic stations are divided into standard hydraulic stations and energy storage hydraulic stations.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071