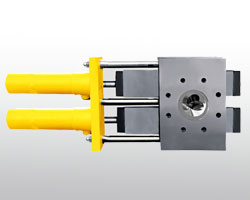

Continuous mesh screen changer

There is no need to shut down and spend labor. According to its design, it can be divided into two main types: interchangeability and continuous type.

The interchanger has two identical groups. One of them is installed on the melt flow path. When the net group becomes dirty, replace it with another set of clean groups. At the same time, the old same group was replaced. The two sets of nets are mounted on the same steel plate, revolve around one axis, or slide along the guide rail in a straight line. The former is operated manually by lever, while the latter uses hydraulic pressure to move back and forth from one side to the other. Another way to replace the net is to use a valve to make the solution flow from the blockage of the same group to the new group.

Continuous mesh screen changer: the continuous screen changer moves the new network gradually to the melt flow while removing the old network. The speed of changing the network can be automatically adjusted according to the impurity quality. The continuous screen changer can eliminate the pressure and melt temperature changes caused by intermittent operation.