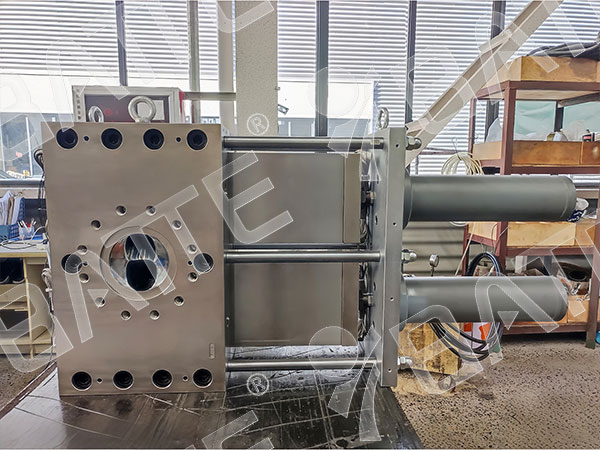

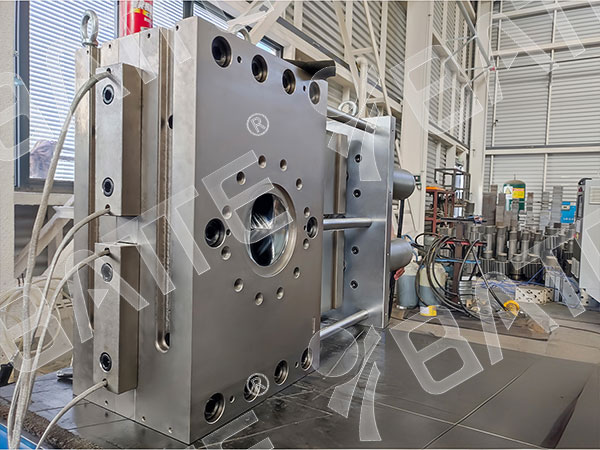

Dual-Plate Non-Stop Screen Changer

The dual-plate non-stop hydraulic screen changer is a critical piece of equipment for polymer extrusion production lines. It primarily filters impurities in the melt (such as carbides, gels, or unmelted particles) to ensure consistent product quality. Its core advantage lies in enabling screen replacement without halting production, thereby avoiding the production interruptions, material waste, and increased energy consumption associated with traditional shutdown screen changes. This significantly enhances production efficiency. Application areas include continuous production lines for plastic films, pipes, fibers, and cable jackets.

Structure and Working Principle

The system comprises the following core components:

Dual-station or multi-station filter plate: Utilizes a parallel design where one set of filters operates while the other is changed, enabling rapid switching via hydraulic drive.

Hydraulic power unit: Supplies high-pressure oil to drive the piston, precisely positioning the filter slide plate. Pressure fluctuations during switching are controlled within ±1%.

Sealing System: Incorporates high-temperature alloy sealing rings with hydraulic compensation structures to ensure zero leakage under melt pressures (typically 10-50 MPa).

Control System: Integrates PLC and pressure sensors to automatically trigger the screen change program when pressure differential reaches a preset threshold (e.g., 5 MPa) due to screen clogging.

Primary Applications

Plastic Extrusion Lines: Suitable for extruding various plastics including PE, PP, PVC, and PET into products like pipes, sheets, plates, films, and pellets.

Chemical Fiber Spinning: Maintains continuous filtration during melt spinning to ensure fiber uniformity and strength.

High-Transparency Product Manufacturing: For impurity-sensitive products like cast film, blown film, and optical films, pressure fluctuations drop to zero during screen changes, preventing surface defects (e.g., black spots, streaks).

Food Processing: Meets hygiene and continuity requirements for food-grade production.

Rubber and Ceramic Melt Filtration: Used for rubber extruders, rubber filters, and ceramic melt filtration.

Typical Application Scenarios

Pelletizing Lines: Suitable for recycling and modified pelletizing of polymers like PP, PE, PET, and PA.

Film and Sheet Production: Suitable for film production of materials like BOPP, CPE, HDPE, and sheet production of PP, PE, ABS, etc.

Hollow Products and Strapping: Used in production lines for hollow panels, expanded polystyrene foam, and PP/PET strapping.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071