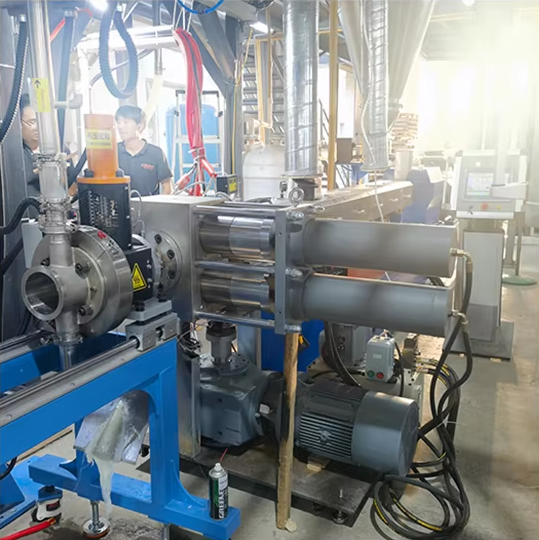

Dual-Column Large-Area Screen Changer

The Dual-Column Large-Area Screen Changer is an industrial equipment specifically designed to address demanding material filtration and continuous production requirements. With its unique structure and performance, it is widely used in the processing of polymer materials such as plastics and chemical fibers.

Its structural design highlights the integration of “dual-column” and “large-area” features. The dual-column architecture, paired with a hydraulic drive system, enables simultaneous screen changes across two workstations during screen replacement. While one workstation remains in filtration mode, the other performs screen replacement. This rapid and smooth switching process requires no production downtime, fundamentally eliminating the production interruptions and material waste caused by shutdowns in traditional single-workstation screen changers. The “large-area” filter design significantly enhances filtration efficiency by increasing material flow cross-sectional area. This enables processing of high-viscosity, high-impurity materials (such as recycled plastic pellets) while reducing flow resistance, lowering energy consumption, and ensuring stable production pressure.

Performance-wise, the equipment features high-pressure and high-temperature resistance, accommodating diverse processing temperature and pressure requirements. Its user-friendly filter replacement operation reduces labor maintenance costs. In practical applications, it precisely matches scenarios such as pipe and profile extrusion, sheet and film production, and filled/modified plastic processing: When filtering recycled materials, it efficiently removes impurities to ensure product appearance and strength. For high-end product manufacturing, it reliably controls material purity, reducing defect rates.

For enterprises pursuing efficient and stable production, the dual-column large-area screen changer is not only a key device for enhancing filtration quality but also a vital support for achieving continuous production and lowering overall costs. It provides robust assurance for efficiency upgrades in the polymer materials processing industry.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071