The structure of the screen changer and the choice of control system

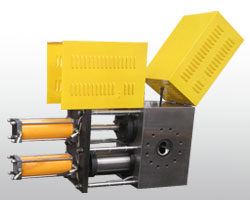

Structure of screen changer

In order to ensure the filtering effect, the screen changer is generally composed of three parts: support plate (shunt plate), auxiliary plate and filter screen, and the filter screen is generally made of metal woven mesh. But sometimes for special needs, silk screen and sand filtration are used as polyester. Nylon is coated with sand to remove gel and impurities. In order to increase filtering face and improve filtering capacity, plug-in filters have been developed by W&P, JSW, Kobe and other manufacturers in large production lines.

The SWZ bucket filter screen changer is mounted parallel to the special support plate. Its filtering area is much larger than that of flat net with diameter. Each filter element consists of a perforated support basket and a filter insert. Inserts are usually made up of two layers of metal mesh. The insert can be drawn, cleaned and reused.