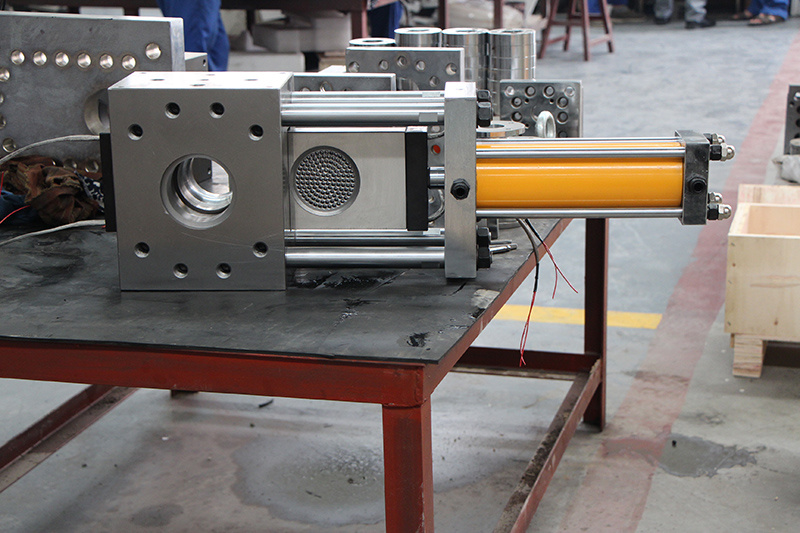

The Characteristics and Configuration of Batte Single Plate Quick Screen Changer

Characteristics of hydraulic single plate screen changer

Single plate type quick screen changer, also known as the single plate dual station hydraulic screen changer, has been widely used in the market due to its simple structure, high cost-effectiveness, wide range of use, and the characteristics of no downtime, no material leakage, smooth flow channels, and simple operation. The plate rapid screen changer is simple in structure and convenient in connection. It can be used in direct connection with single screw extruder, twin screw extruder and reaction kettle of different specifications to simplify the material flow channel.

Application of Single Board Fast Screen Changer

The plate type quick hydraulic screen changer adopts a pressure activated sealing device, which meets the extrusion production of almost all thermal plastics and the polymerization production of polymer chemical raw materials. The porous support plate after rheological optimization of the material effectively reduces the shear of the melt during the extrusion process. Special materials can optimize the porous plate structure based on material characteristics and process requirements, effectively improving filtration permeability and filtration quality. During the screen changing process, it can achieve non-stop screen changing and achieve the effect of no material leakage. Equipped with suitable hydraulic stations according to the size of the screen changer, the fast screen changing time is basically controlled within 2-5 seconds.

Configuration of extrusion melt filter plate type screen changer:

The standard configuration of the single plate quick screen chagner includes three major components: the main body of the screen changer, the energy storage hydraulic pump station, and the electric control cabinet. Users can choose the configuration according to their actual needs. The commonly used heating methods for screen changers include external heating plates or coils, built-in heating pipes, or comprehensive heating methods. They can also be customized for heating medium according to requirements, which is energy-saving and efficient. For corrosive materials, anti-corrosion treatment can be carried out or anti-corrosion materials can be used for processing. When selecting a screen changer, multiple factors such as applicable output, material viscosity, material composition, filtration accuracy (filter mesh size), and equipment pressure should be comprehensively considered. The specific selection depends on the actual process parameter design.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071