Screen changer for plastic recycling extrusion

In the production of plastic extrusion, there may be various impurities and foreign objects in the raw materials, as well as fine crystal particles with incomplete plasticization. Especially in the recycling process of recycled plastics, there are various impurities such as paper scraps, aluminum foil, sand, iron scraps, copper wire, wood scraps, and ineffective defoamers. If no screen changer is installed for impurity filtration, the presence of these impurities will cause a decrease in product quality, an increase in defective products, and production interruption, It may even cause damage to the extrusion equipment, resulting in huge waste of raw materials, high production costs and energy consumption, relatively reduced production capacity, and increased labor intensity for workers.

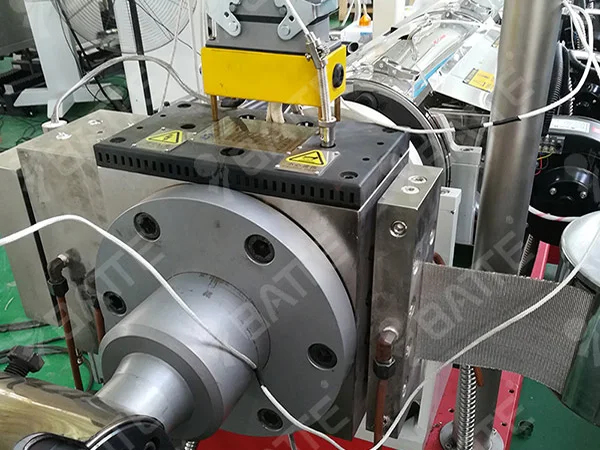

screen changer for plastic recycling extrusion

The basic configuration of the screen changer consists of the main body of the screen changer and a hydraulic power system. An electronic control system can also be selected to more accurately control the screen changing time. The processor screen changer needs to switch freely from the filtering station under normal working pressure, and also to ensure no material leakage. This puts high requirements on the quality and manufacturing of the screen changer, and only low-quality and unqualified screen changers will experience material leakage. To obtain a qualified plastic extruder hydraulic screen changer, the structural design should be reasonable first, followed by a guarantee of material (alloy steel), and then in terms of processing technology and accuracy_ Accurate installation and experience in assembly and debugging are necessary to ensure that the screen changer does not deform under high temperature and pressure conditions, always maintains precise fitting accuracy, and does not leak materials for a long time.

plastic extruder hydraulic screen changer

In the production of recycled plastics, recycling and granulation are generally carried out. Crush the recycled plastic, clean, dehydrate, and dry it before proceeding with granulation production. The configuration of the granulation unit is generally adopted Composed of feeding machine, feeding device, granulator, screen changer, granulator mold, granulator, etc. In terms of granulation process, it is divided into water pull-down strip granulation, water ring granulation, hot cutting, etc. Different granulation processes require different production requirements, and the types of screen changers chosen are also different. The screen changer is divided into single plate dual station screen changer, double plate dual station screen changer, double column dual station screen changer, and mesh belt fully automatic screen changer, all of which are suitable for granulation production and can be selected according to different working conditions and production requirements.

Plastic extruder hydraulic screen changer

The mesh belt type fully automatic hydraulic screen changer is a true fully automatic screen changer, which adopts a mesh belt type filter screen and automatically moves the screen according to the material pressure. There is no need to manually change the screen until the filter screen is taken away, and it is suitable for various granulation production processes. The mesh belt type fully automatic mesh changer has basically no material pressure fluctuations (control range can be set), and no power is required to change the mesh. It relies on the pressure of the material flow to drive the mesh belt to automatically move the mesh, and the mesh moving process is smooth and stable. The limitation is the use of water-cooled sealing, which starts the outlet heating for mesh routing during mesh routing. There is a certain time process and requires a screen change time interval of more than 30 minutes to achieve automatic mesh routing control. The cost of filtering the mesh belt is relatively high, and the waste brought out by the mesh belt is relatively high.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071