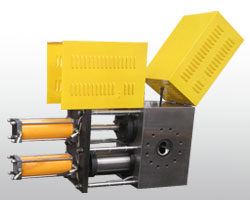

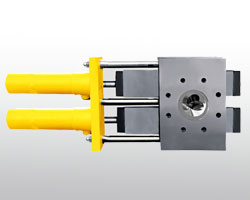

continuous screen filter screen changer

Batte melt pump Co., Ltd. specializes in the development and production of continuous screen filter, providing high - end technology and energy saving products for extruding equipment enterprises. They bring new products to the exhibition.

The continuous screen filter, developed for four years, is an innovation in the plastic extrusion industry, which has changed the production mode of plastic filtration, and the energy efficiency ratio has been leaped on it. Especially for the application of the extruded board, the cost per ton is about 400-600 yuan, the weight ratio of the melting weight is reduced by 10%, the labor strength of the staff is greatly reduced, the quality of the product can be greatly improved, and the original silk screen is saved, and it has the characteristics of environmental protection. No wave exchanger can be said to be a subversion of the whole industry, high pressure, no material, no volatile material, can be applied to the blowing machine, wire drawing machine, packing belt, leaking machine, casting machine, tube machine, sheet machine, granulator, chemical fiber shotcrete equipment and any other extrusion equipment never stop. The rotary double screen screen without screen filter is more effective for the enterprises of the aluminum plastic composite board and PS foamed aluminum plastic plate. Its design principle makes the waste better discharge through the double knife high speed kneading function, and can make the plasticizing to reach the highest melting index. The unique advantages of Le Neng's energy saving, environmental protection and labor cost have attracted countless customers.