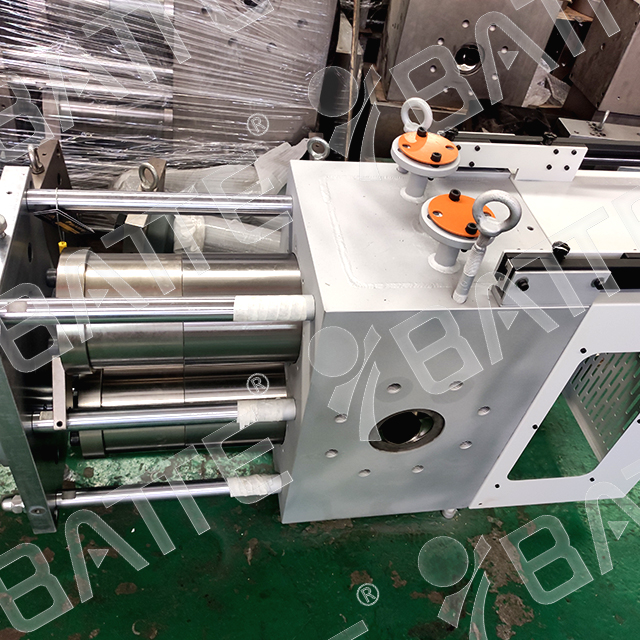

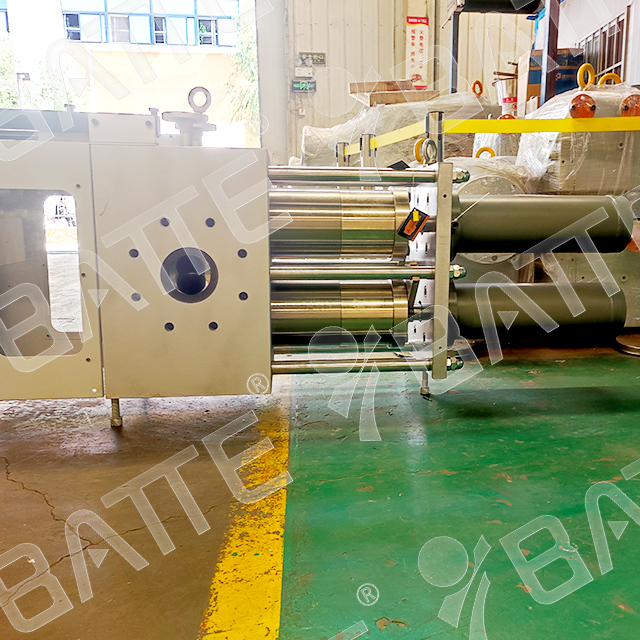

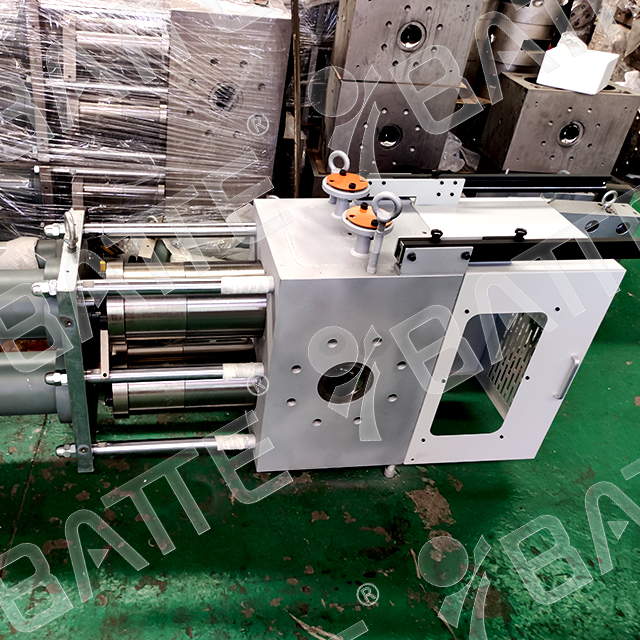

Selection Scheme of Automatic Extrusion Screen Changer for Waste Plastic Recycling and Granulation

The extrusion screen changer for waste plastic recycling and granulation is a double column large filter cartridge screen changer, made of high-quality alloy steel and specially processed through multiple processes such as quenching and tempering, nitriding, and precision grinding. The dual screen and dual channel design are used, and the filter screen is wound to increase the filtering area. When the filter screen is not replaced, the two screens work simultaneously, and the screen is replaced alternately. The screen changer is designed with a stable structure, which does not stop the machine, does not interrupt the material flow, and does not interrupt production, meeting customer demands for high production capacity High quality production demand, especially suitable for the production of recycled granulation, cast film, board, sheet and other products.

hydraulic extrusion screen changer

Characteristics of automatic screen changer for double column four station granulator

1. Four channels and four workstations, with four screens working simultaneously, provide a relatively small chamber and a larger filtration area;

2. Rigid sealing structure, no leakage;

3. Reasonable feeding and exhaust structure to ensure continuous and stable product;

4. There are three filter screens in operation during mesh replacement/material introduction and exhaust, and the pressure fluctuation during the mesh replacement process is small;

5. PLC control and automatic operation control can be achieved, reducing the manual intervention cost of operators;

6. It can achieve automatic alarm and control, ensuring the safe and stable operation of the system;

7. Targeted structural design can be made for processes such as polymerization lines and blending.

continuous screen changer for extruder

Technical parameters of automatic screen changer for recycling and granulation of waste plastics

1. Working temperature: ≤ 350 ℃;

2. Working pressure: ≤ 50MPa;

3. Pressure difference: ≤ 20MPa;

4. Applicable melt viscosity: 100~30000Pa. s;

5. Heating method: electric heating/heating medium heating.

Automatic Screen Changer for Waste Plastic Recycling and Granulation

Option plan for screen changer for recycling and granulation of old plastics:

1. For high corrosion conditions - choose a high corrosion resistant material solution;

2. Mobile installation trolley, integrated with hydraulic station and electrical control system, convenient for on-site maintenance;

3. Optional automatic control system, integrated PLC control system, easy to operate;

4. Integrating the connection and control of components such as melt gear pumps, mixers, start-up valves, and underwater cutting die heads, a complete solution can be provided.

hydraulic extrusion screen changer for plastic extruder

Email: info@battemachinery.com

WhatsApp: +86 158 38331071