The application of scene screen changer

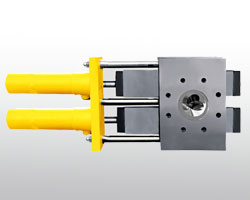

During extrusion, impurities mixed into melt plastics not only affect product quality, but also hinder normal production. Therefore, filters are installed on extruders to separate and remove impurities, ensure product quality and stable production. The filter device is generally composed of a filter plate and a filter stack. Filtration screen use - after a period of time, due to impurities and other blockage mesh needs to be replaced, the replacement of the filter screen using the filter exchange (screen changer).

With the rising price of raw materials, in order to reduce costs and increase profits, plastic enterprises have increased the proportion of recycled materials or inferior materials, which put forward requirements for the filter reliability of production lines. For some products abroad, such as gas pressure tubes, the requirement of filter fineness of polymer melt has been written into quality documents, because its physical properties (such as impact resistance) are directly related to the filter fineness in the production of products, which promotes the application and development of screen changers.

At present, this kind of filter exchange (screen changer) of extruder has been successfully applied in plastic processing such as film blowing, granulation, recycling, pressing, spinning, injection molding, blow moulding and foaming.